Background:

I am working on implementing the FDC1004 for liquid level sensing. In Table 1 of application note SNOA935A (http://www.ti.com/lit/an/snoa935a/snoa935a.pdf), it indicates that a disadvantage of direct sensing is that "Sensors and electronics are separated" while remote sensing has the advantage of "Sensors and electronics can be integrated on one board".

The application note defines direct sensing as "sensors directly on the container" and remote sensing as "sensors located in close proximity to the container."

Question:

For direct liquid-level sensing with the sensors directly on the outside of a container, do the sensors actually have to be on a separate PCB? Or, is there some configuration which would make it okay to have all the drive electronics on a single PCB?

Two example configurations which I would like to understand whether they would significantly influence the measurement to the point where I should not bother prototyping:

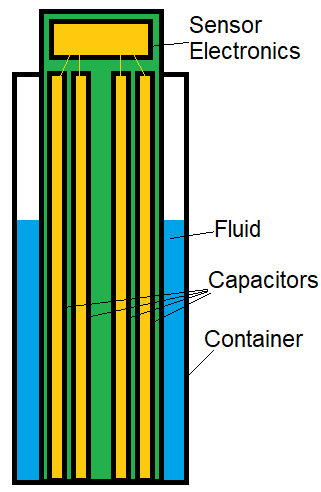

- The sensors and electronics are all on the same PCB, but the PCB extends beyond the edge of container. Only the capacitors are in direct contact with the container and all electronics are positioned such that the portion of PCB they reside on is in contact with free air (depicted below).

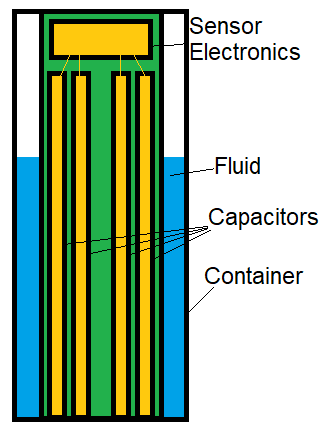

- The sensors and electronics are all on the same PCB. All electronics on this PCB are positioned well above the top of the topmost capacitor and shield (and therefore above the highest level of fluid expected to be measured) and the electronics have a layer of PCB in between the electronics and the container -- only the capacitors are actually in direct contact with the container (depicted below).

Theory and/or other information on why SNOA935A appears to indicate that the sensor electronics must reside on a difference PCB than the capacitors in direct sensing applications would be greatly appreciated.