Hi

I would need a really low power rain sensor in the range of <100uA's - checked the FDC familiy but it seems it is in range of 7-800uA-1 mA, at least the ones I've checked.

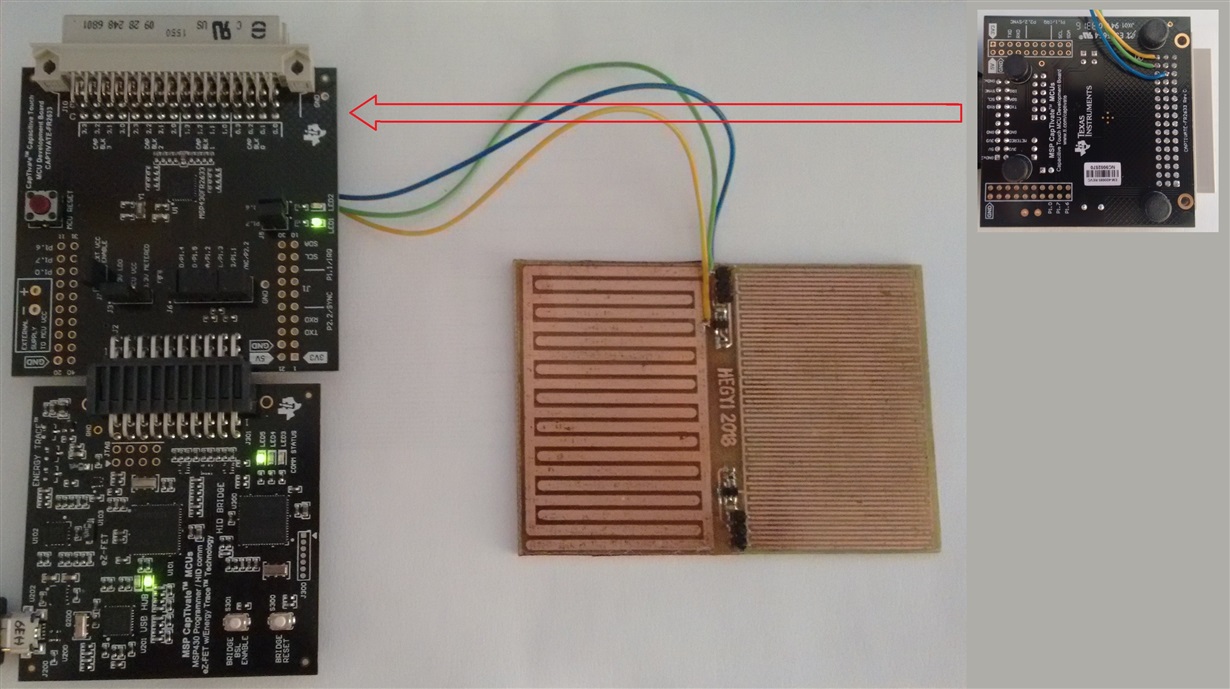

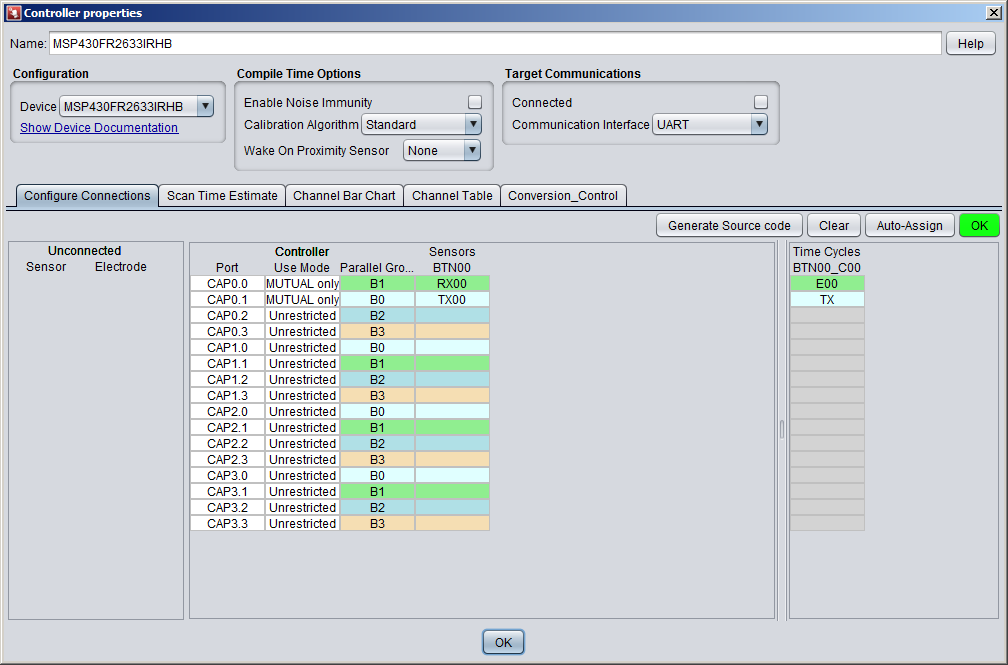

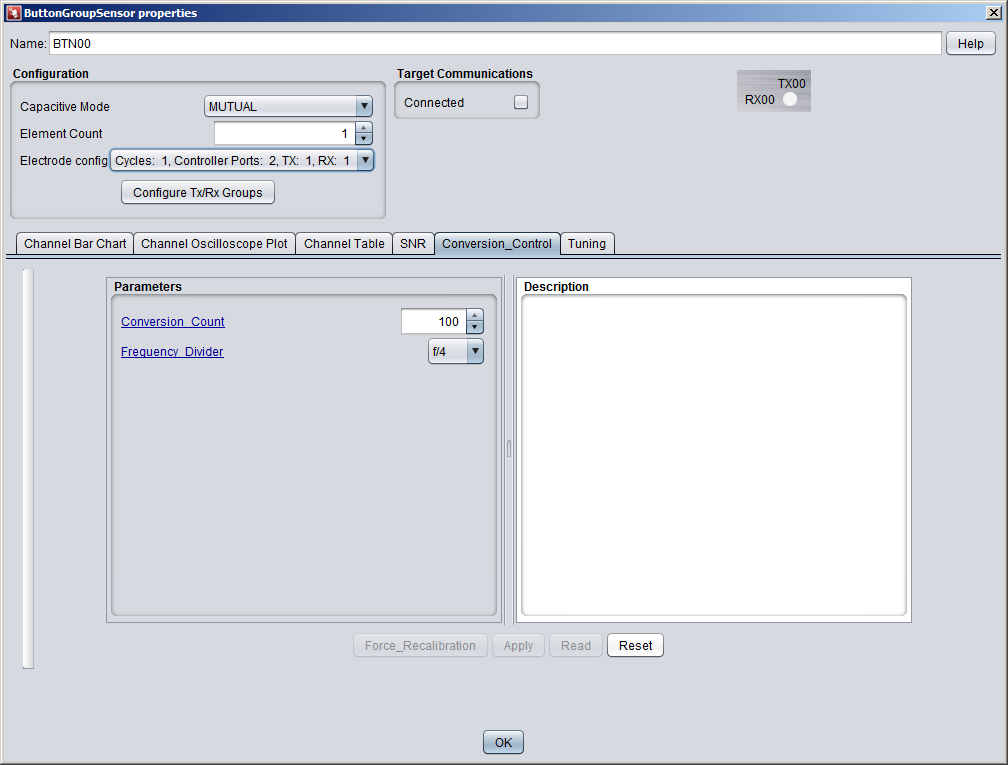

Noticed the MSP430FR2x family which has a really low power cap sense (<10-20uA) but CapTIVate chips seems to be for touch which rejects rain - can they be used as rain sensors with some reconfiguration?

Any idea is welcome,

TY