Hi all,

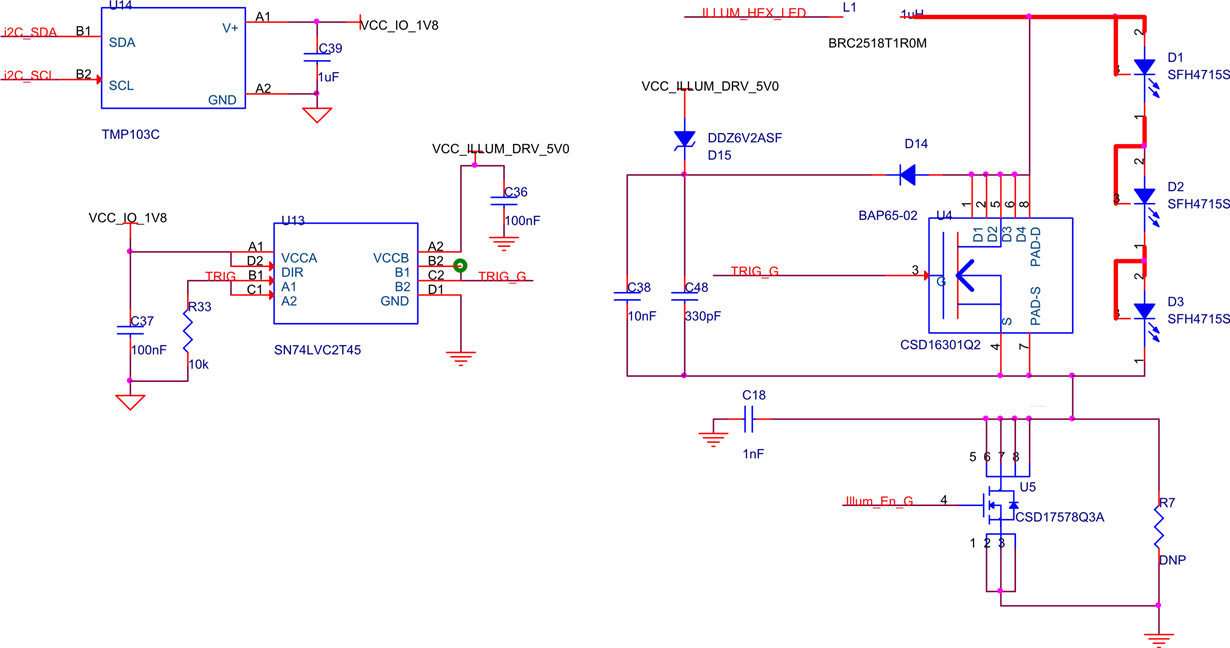

The OPT8241 CDK provides the reference for Laser diode driving,By the way,what the part of "HEX_LED ckt" is used for?

Can you provide me with some reference about LED drive circuit?

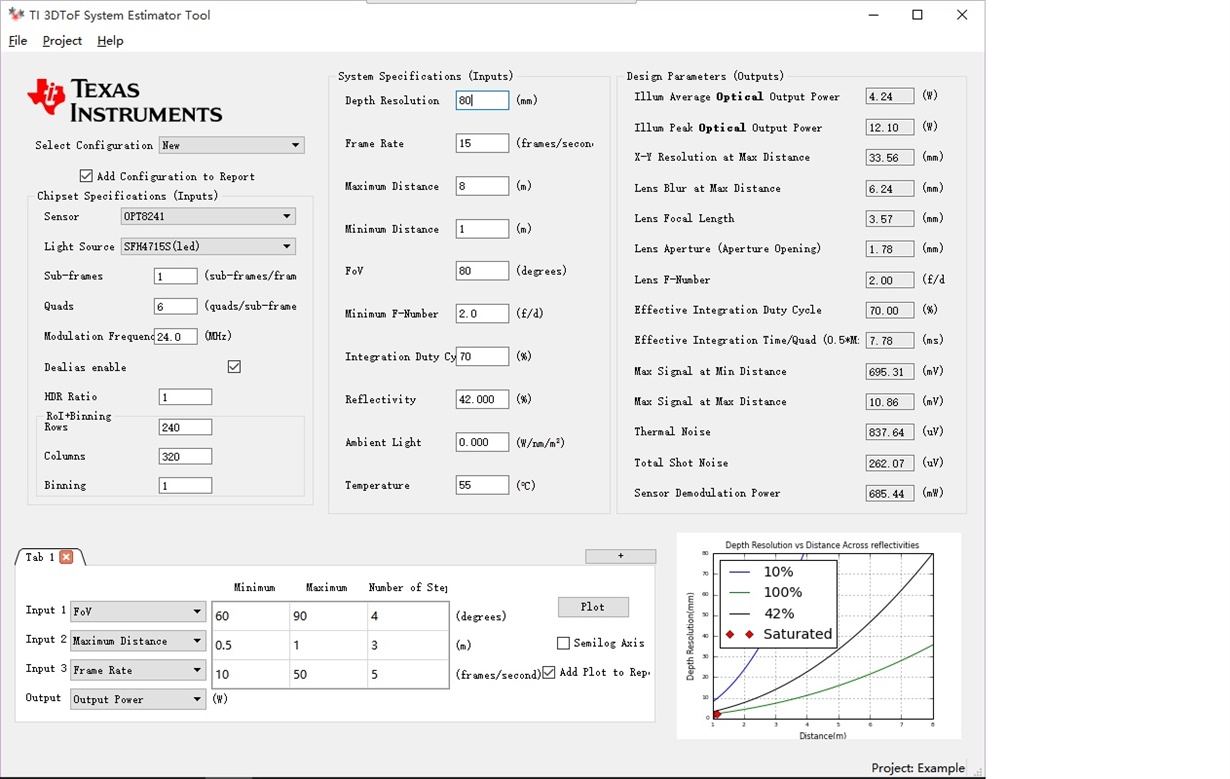

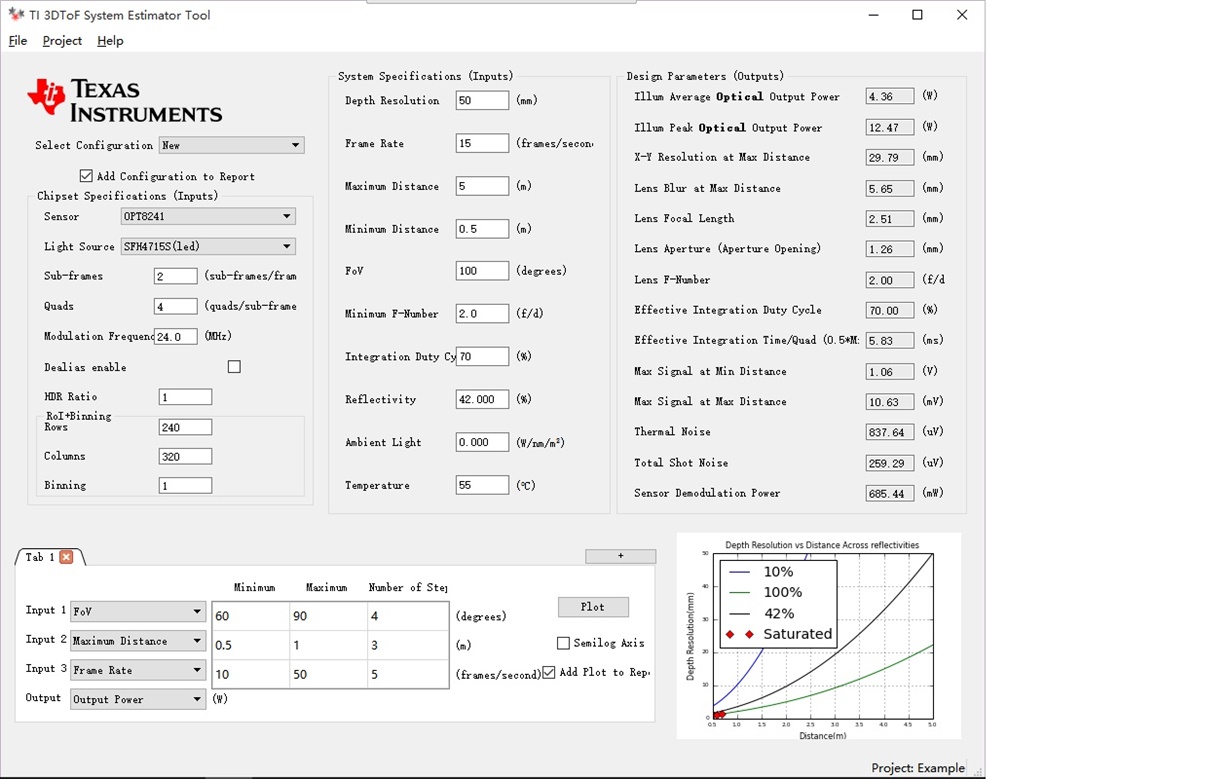

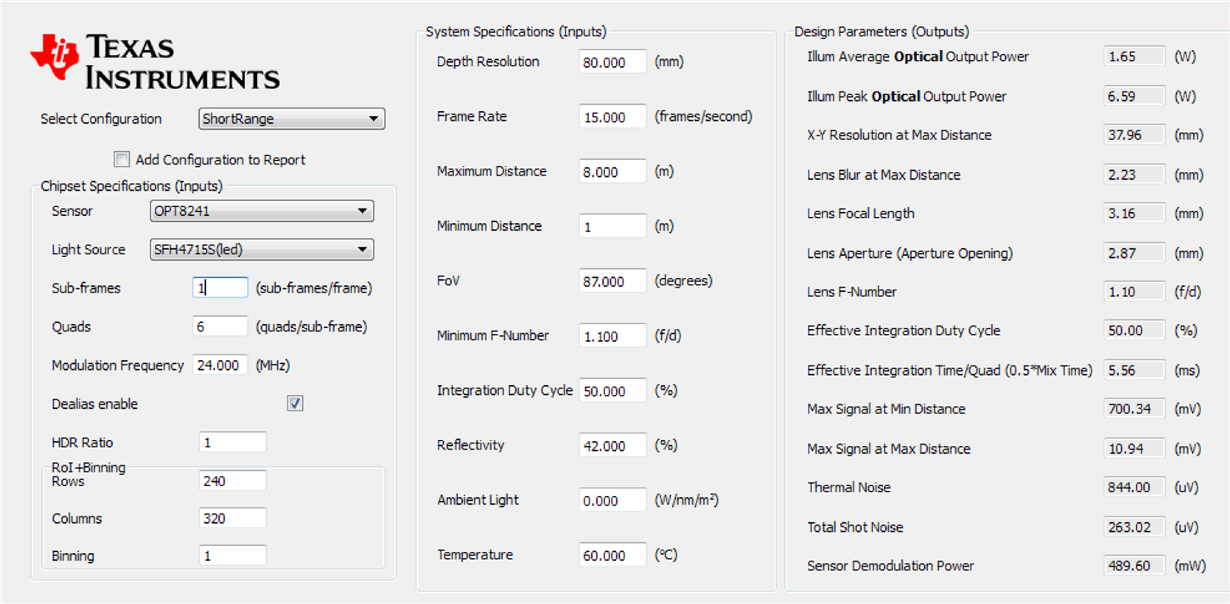

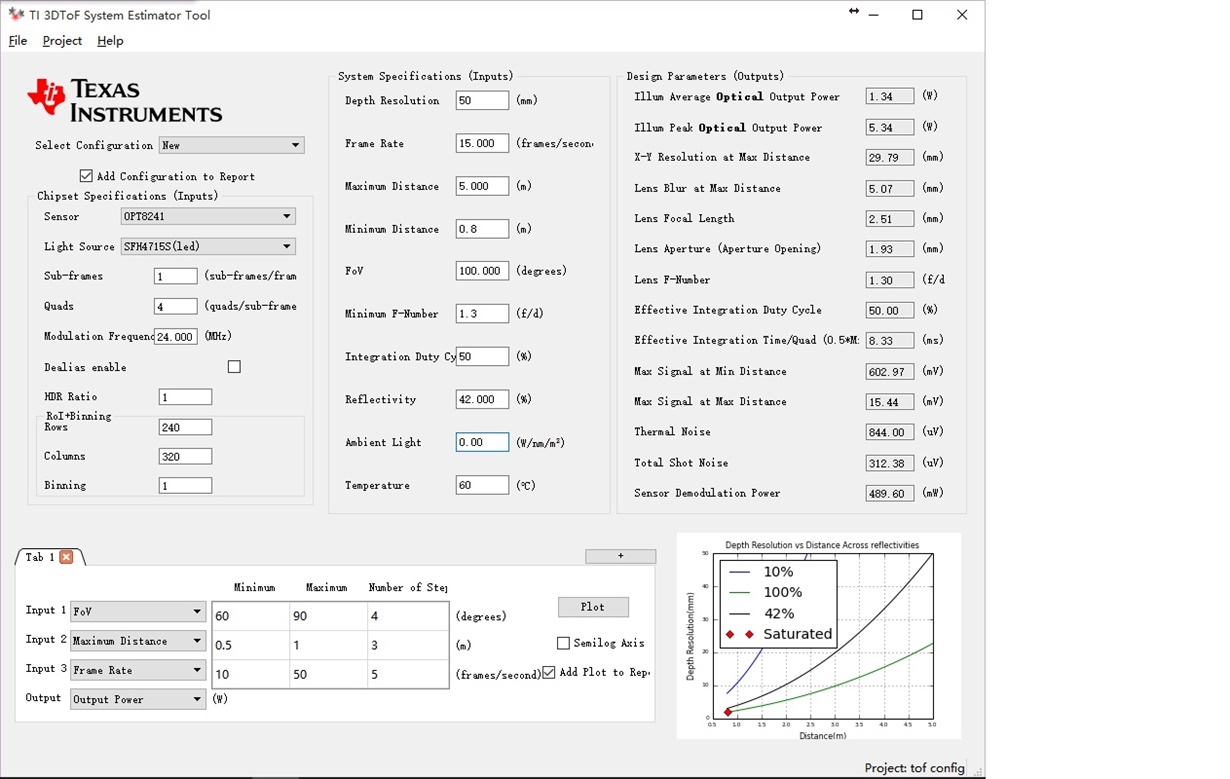

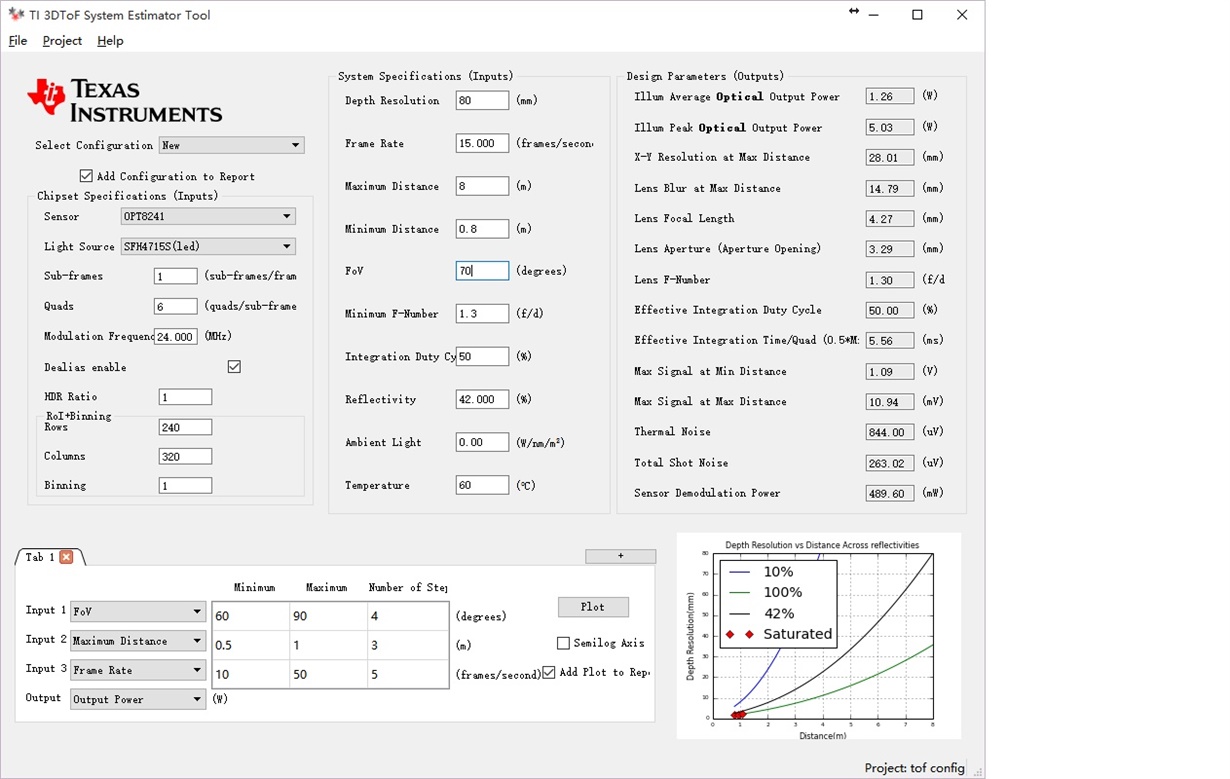

The input voltage is 5V,LED 4715S,FOV 100deg,Max dis 8m or farther.

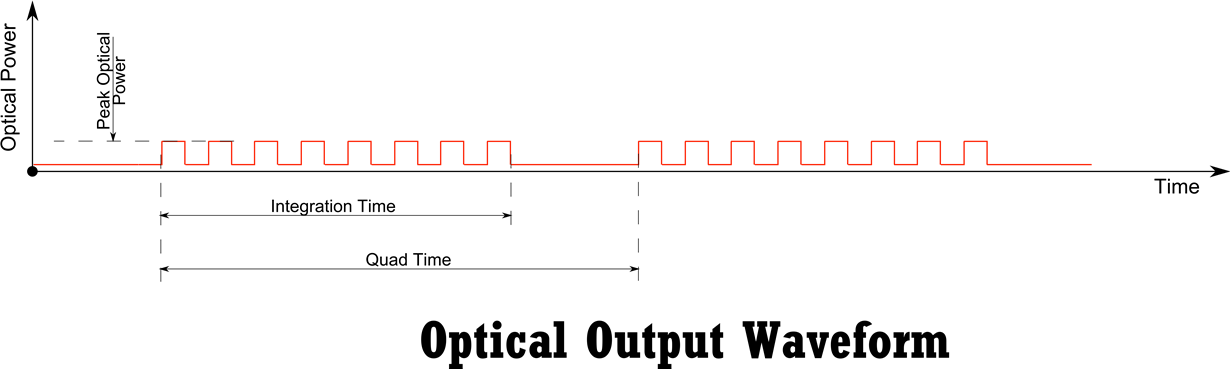

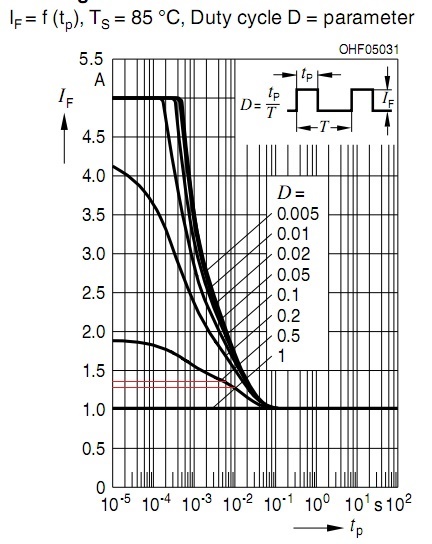

can 2 LEDs do this (4715S VF 3V,IF 1A)? Does "Path Delay Correction" needed here?