Other Parts Discussed in Thread: TDC1000

I'm posting this set by step setup for folks who need to perform level sensing from the bottom of a metal container. I'll turn this into an App Note eventually.

1, Read my app note on transducers to get an understanding about how transducers work, how to select them and how to mount them externally.It can be found found at: www/ti.com/lit/pdf/snaa266

2. Read my app note on how to configure the TDC1000 in a level sensing application from the bottom. I go over how transducer choices effect system design and how to configure the TDC1000. It can be found found at: www/ti.com/lit/pdf/snaa270

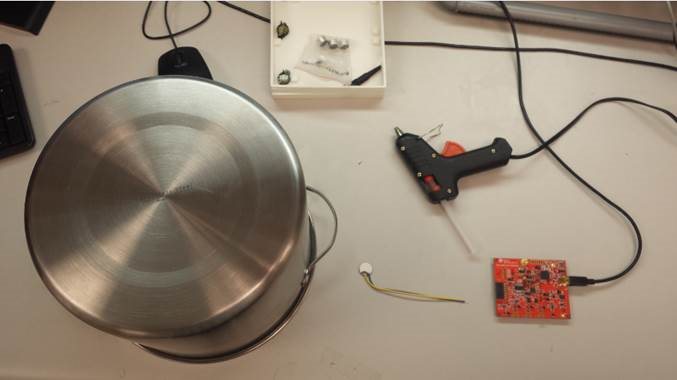

Here’s pics of the assembly process:

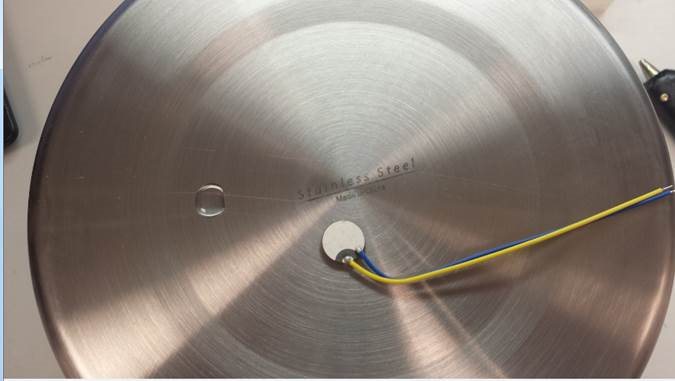

Gluing transducer to container bottom. Notes:

- just enough glue to cover the transducer

- No need for electric isolation (glue isolates)

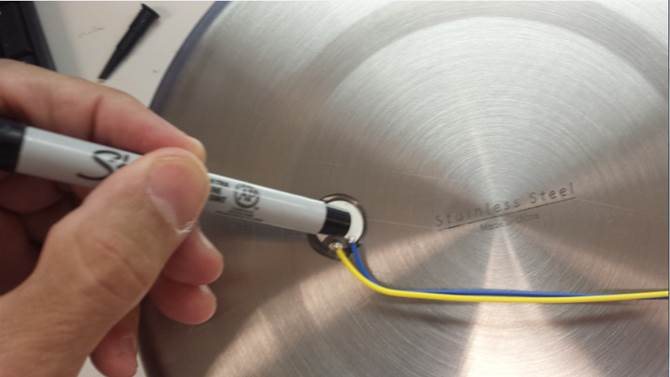

Apply light pressure to transducer while waiting for glue to set.

Side view showing amount of glue.

Top View showing amount of glue.

Hot gluing stage: provides transducer acoustic dampening, transducer protection, and wire strain relief

Adding 4 rubber feet to container bottom to protect the transducer

Test setup: Pot, and TDC1000-TDC7200 EVM, transducer connected to TX1/RX2 (pin 10, 11) on J5

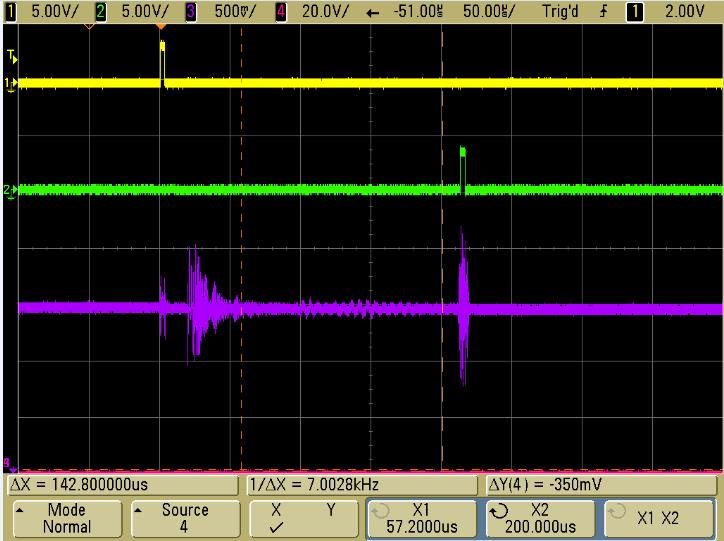

Scope shot with level above 15 cm. Note: it is ~1V p-p, meaning higher levels are easily achievable.

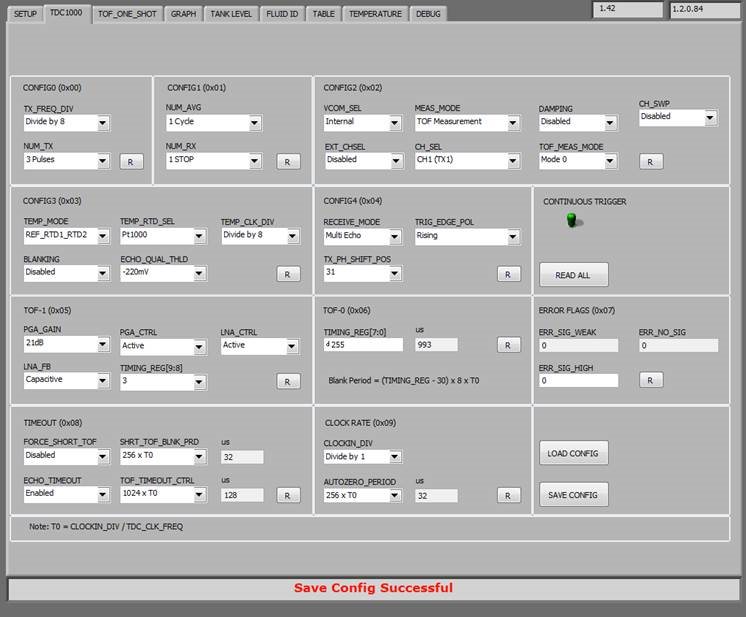

TDC1000 register settings (here’s a good starting point):

Here is a graph of the TOF measurement using the demo while I’m filling it from empty to full (~16cm).