Hi

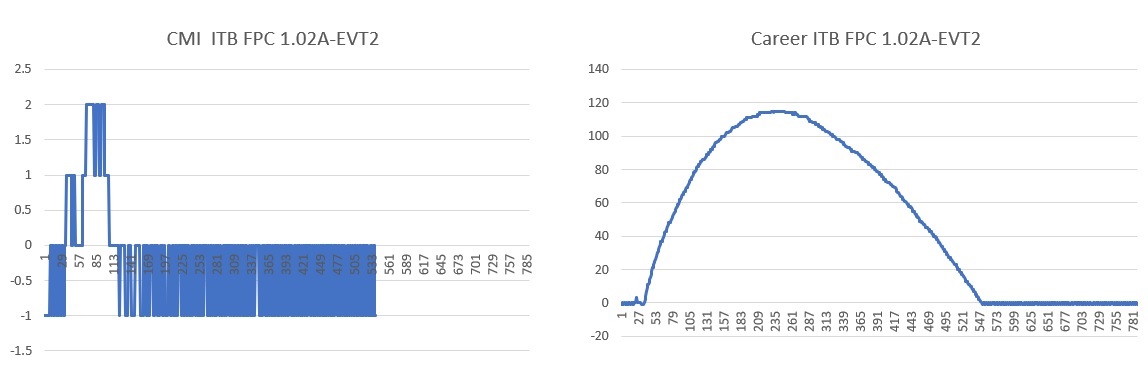

We met a problem that when we put our DUT from ambient into freezer (~ 0 degree), some DUT LDC2112 raw data will change

And we find it's because different FPC vendor (our LC coil pattern is on FPC)

The FPC vendor CMI it's LDC2112 raw data won't change, but FPC vendor Career & Unimicron will change (I attached CMI & Career's data at below)

At beginning we thought it related with thermal expansion coefficient, but when we get data from FPC vendor

FPC vendor CMI's is larger than Career & Unimicron, so seems it not root cause

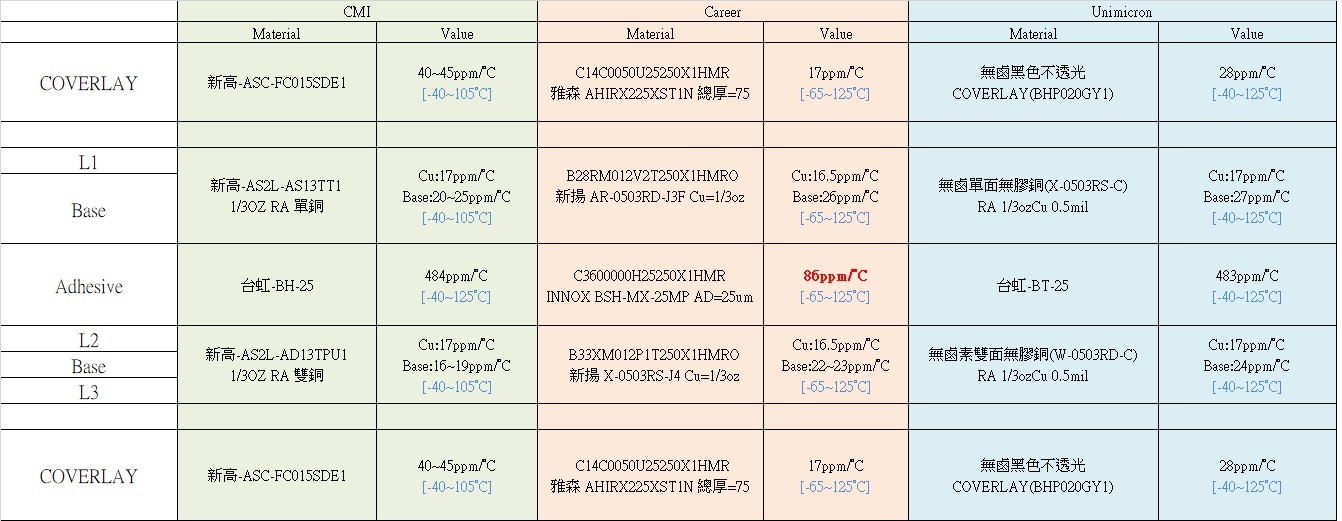

Below is three vendor's stack up(LC coil pattern is at L2/L3)

So could you help check if anything wrong with Career & Unimicron's stackup?

Or if any material's parameter that we need to check?

Or how do we analyze this issue?

Thank you~~

Poki

LDC2112 raw data

Three FPC vendor's stack up