Other Parts Discussed in Thread: DRV5012

We would like to use Digital-Switch Hall Effect Sensors in our RFID readers as tamper protection.

RFID means freq band HF (13.56MHz) and LF (125kHz) together. We need have to investigate both of freq band.

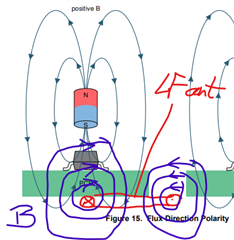

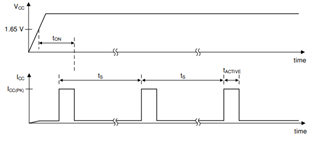

As you know, antenna field is contiunuos changing, the sinusoid signal in the field with period much more shorter than sensor sampling range. The peak magnatic field could reach the sensor Bop, Brp levels.

RFID antenna field could disturb the sensing of sensor at peak points.

The target sensor types are

| DRV5021A2QDBZR |

| DRV5021A3QDBZR |

| DRV5023BIQDBZR |

| DRV5032AJDBZR |

| DRV5032ZEDBZR |

| DRV5033FAQDBZR |

| DRV5033AJQDBZR |

Could you tell me any info about interference?

Will antennas magnetic field disturb the sensing?

Could you tell me more about sensor internal sampling process (instantaneous or average is used)?

What kind of sensor type do you prefer for our application?

References:

Attila