Other Parts Discussed in Thread: LDC1101

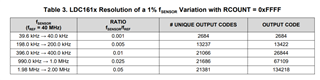

Could I get some more information about Table 3 in Optimizing L Measurement Resolution for the LDC161x document?

For example: The line 1.98MHz - 2.00MHz shows unique codes 21381 and output code 134218.

Using formula: Fsensor = Fref ( Datax / 2^28), the Datax = 13,421,772. That's exactly 100 time the output code. Are those values the changes that occur when the sense frequency changes 1% ?

If so, what actual value will be in the Datax register? Will the Datax register contain the 13,421,772?

What does the 21381 represent. Does that mean that there will be a change of 21381 different values in the Datax register when the sense frequency changes 1% ?

I would like to understand what values are in the Datax register when the sense frequency is 2 MHz and how the Datax register changes for a 1% sense frequency change and what kind of resolution is possible.

Some actual number value examples would be very helpful showing the Datax register at 2 MHz and at 1.98 MHz and at least a few sequential values that would be in the Datax register while the frequency changes very slowly.

Sincerely,

Gary Tiani