Other Parts Discussed in Thread: FDC1004, FDC2114, LDC3114-Q1, FDC2114-Q1

Hello, teams.

I use FDC2114EVM for touch sensor to On/Off LEDs.

10x10 square pcb is attached 3T ABS plate.

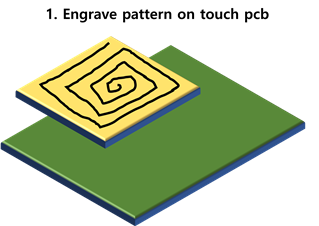

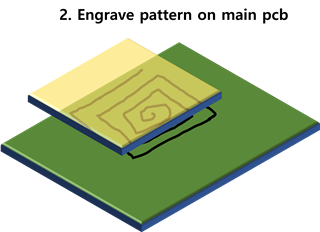

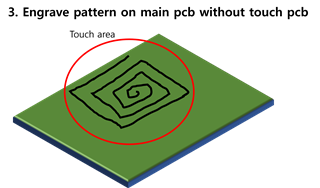

like this

finger ↓↓

10x10 PCB ***

When finger touch a plate, sensor value is change 550 to 548. (In my test condition)

but a wire around below the PCB, sensor value is change 550 to 530.

Maybe when I make a 10X10 engraved pattern PCB, It also expect same effect?

Best regards,

Kim.