Other Parts Discussed in Thread: TMAG5170

I am currently working on a project that could use the TMAG5170A1EDGKRQ1 and I need more information about these components :

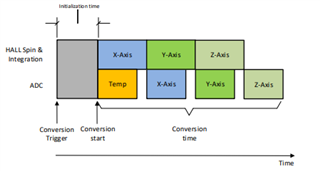

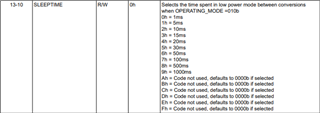

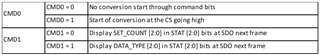

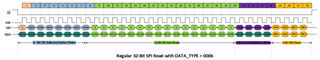

- I have difficulty to understand how we can choose the channels we want to measure and how to read and interpret the transmitted data. Can you explain me that ?

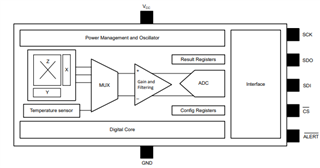

- Can you explain me how data are processed inside the component ?

- Can you give me the FIT-Rate for this component at 55°C ?

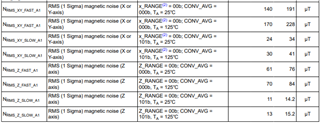

- Are filters included in the component analog or digital ?

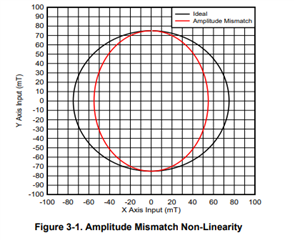

- What is the minimal magnetic field value the component can measure ? In the datasheet it is written ±50 mT, does it mean the component can measure all magnetic field in this range (even 1 mT) or is there a minimal value below which the sensor doesn't pick up the magnetic field (for example 20 mT)?

Thank you in advance for your answer. I look forward to hearing from you.

Arnaud LANDRI