Hi,

we have successfully interfaced TMAG5170 and able to read angle result register and see it's getting updated with shaft movement with CRC checks.

a) To meet ASILB,we want to read x,y channel data(0x89,0x8A) and re calculate the angle in degrees with x and y channel data. what is the formula to do this.(we have done required configurations for this in sensor/system configuration)

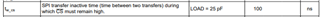

b)Can we implement the following scenario (or) is it mandatory to make chip select high after each command.

- Do chip select low

- send angle read command and read the spi result

- send x channel read command and read the spi result

- send y channel read command and read the spi result

-Do chip select high

Thanks,

P Tulasi Krishna.