Other Parts Discussed in Thread: TMAG5115, TMAG5110, TMAG5111, DRV5055, TMAG5253, TMAG5273

Hello,

I am using the DRV8350FHRTVR motor drive and F280041CRSHS micro in a custom board design. We are currently using InstaSPIN-FOC to control a sensorless BLDC PM motor.

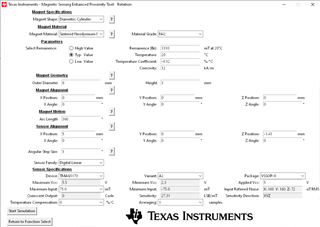

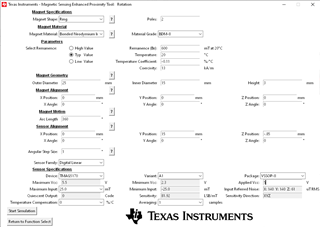

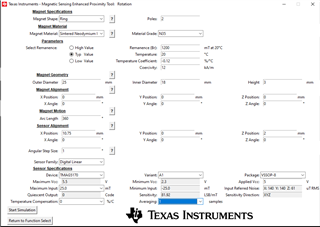

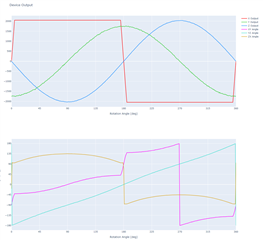

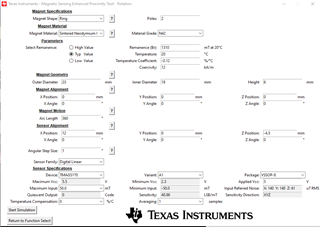

I would like to add position feedback to the system. An off axis sensor will my system the easiest. My motor shaft passes through my board so a TMAG5170 might do the trick.

Will this type of sensor work for a position feedback for a BLDC so I don’t have the typical sensorless startup issues? How do I determine if the sensor/target magnet are in too close of proximity to the stator/rotor magnets or is that not a problem?

Thank you