Other Parts Discussed in Thread: PGA460, ENERGIA, PGA460PSM-EVM, TS12A12511, TMUX6119, TMUX1121, TMUX1122, SN74LVC1G66

Hello,

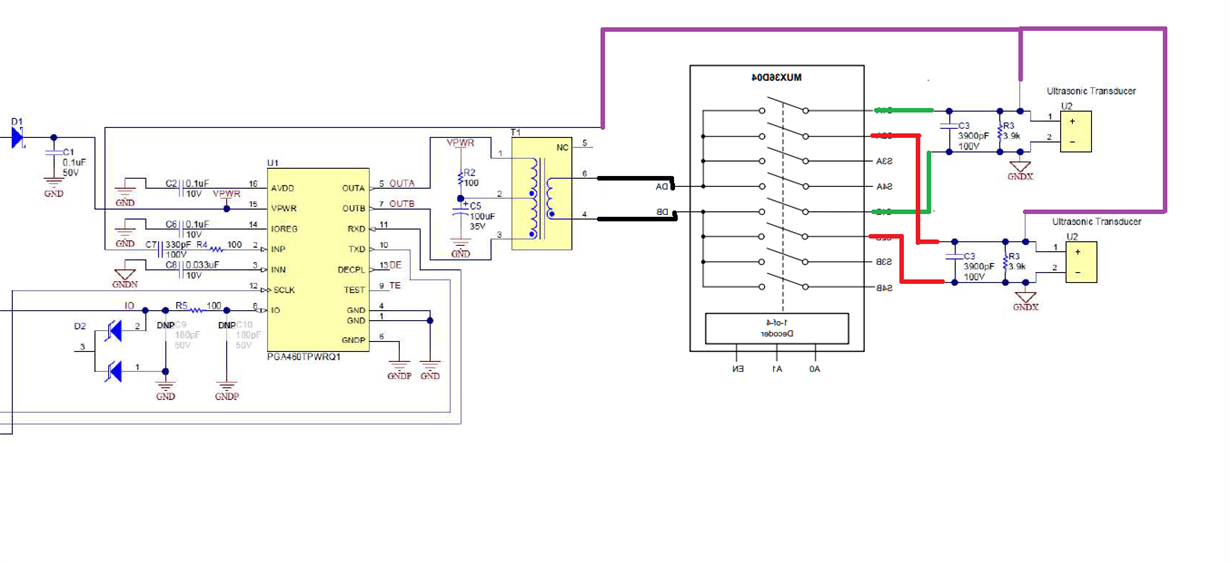

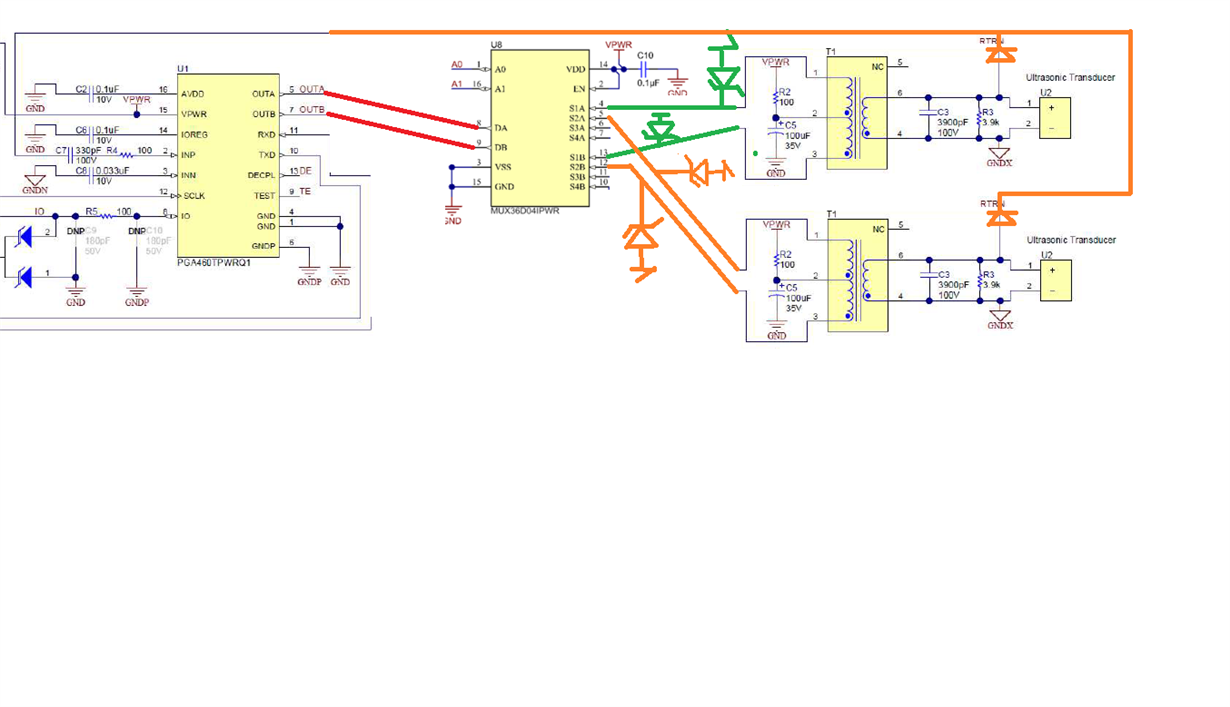

I wanna use 2 transciever sensor that synchronous each other with PGA460-Q1. How can I do? Do I need 2 PGA460-Q1 or can I make this 1 PGA460-Q1?

Best regards.