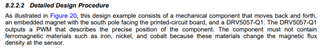

Other Parts Discussed in Thread: DRV5057

Hello,

I am developing a brake system.

I am going to make a product that outputs a brake signal using a magnet and a hall sensor.

I am going to make a brake product that is resistant to heat.

However, while reading the datasheet, I have a question.

In the picture, it is indicated that the compatibility with nickel and cobalt is not good.

I was going to use the DRV5057-Q1 with Alnico magnet.

Can't Alnico magnets be used as indicated on the datasheet?

Does the DRV5057-Q1 calibrate even if the magnet density is changed?

There shouldn't be a problem because accuracy and reliability are so important.

Please let me know if what I understand is correct.

Regards,