Other Parts Discussed in Thread: TDC1000, MSP430FR6047

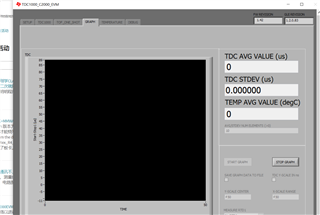

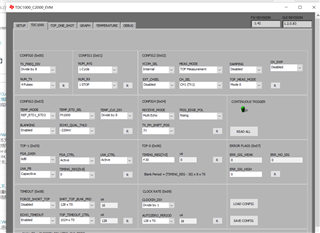

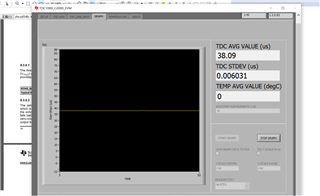

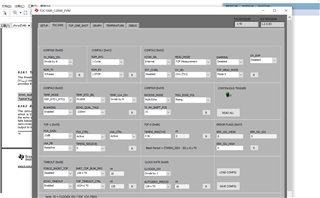

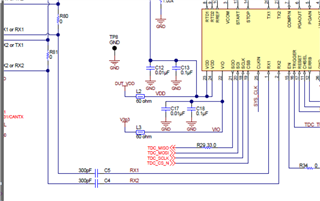

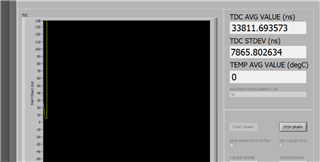

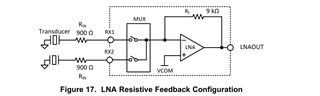

TDC1000-C2000EVM don't work if i choose the LNA_FB in capacitive state ,however,if Ichoose the resistance state ,the TDC1000-C2000 EVM GUI graph will work even without a transducer(the transducer don't connect to the board)