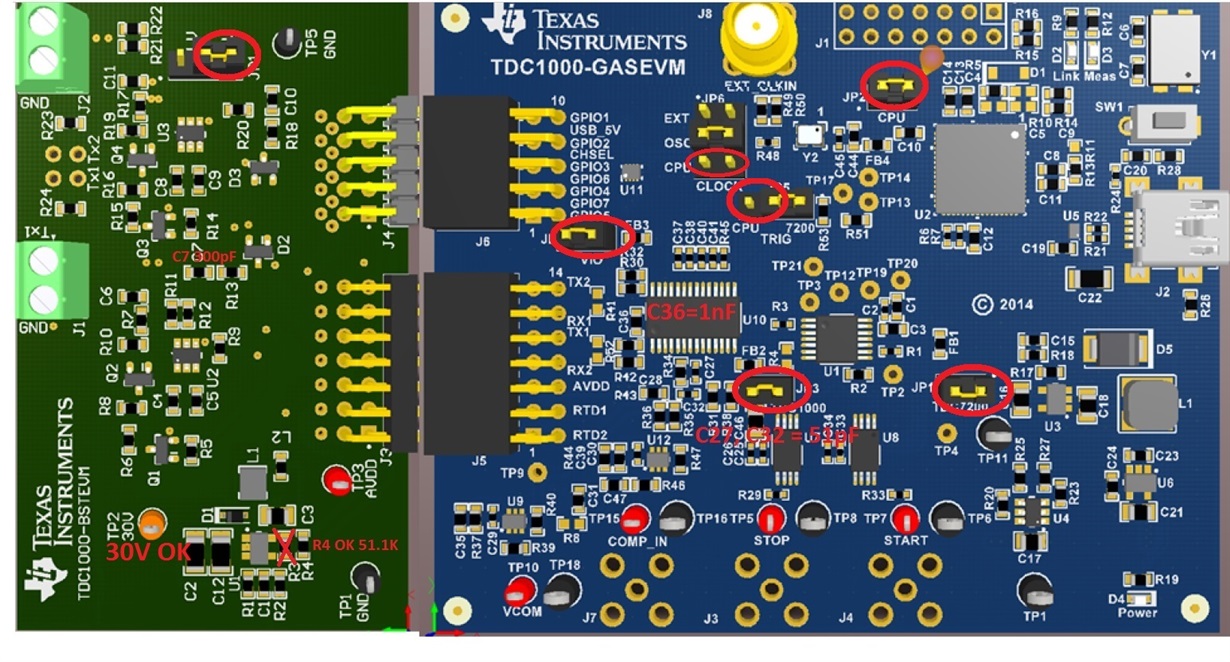

Other Parts Discussed in Thread: TDC1000-C2000EVM, TIDA-00322, TDC1000, TDC7200

Hello,

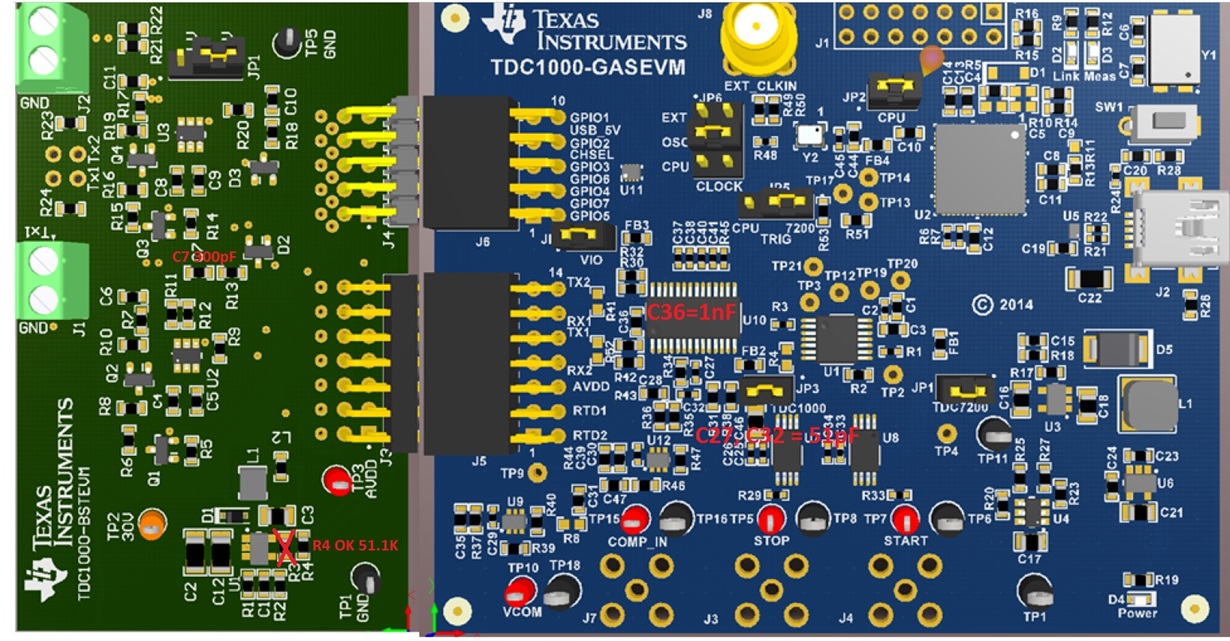

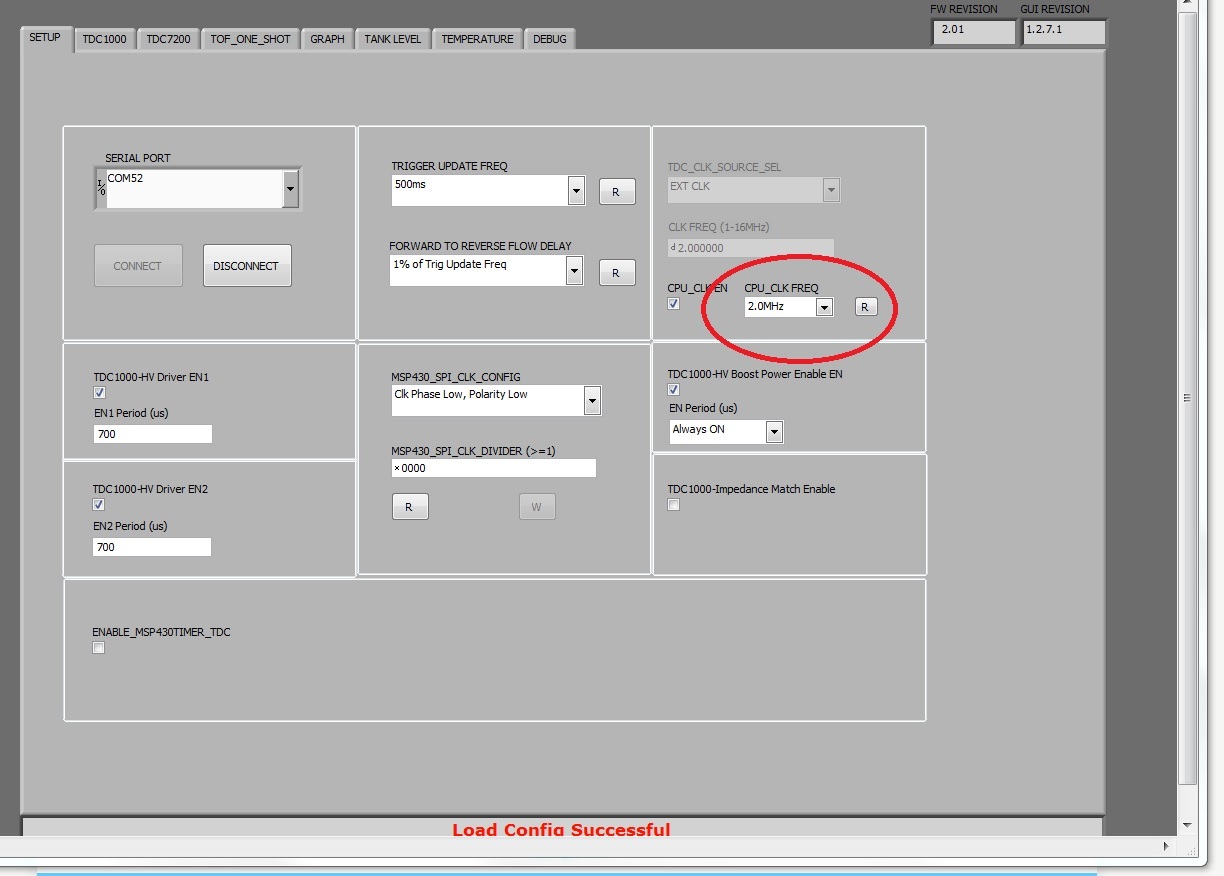

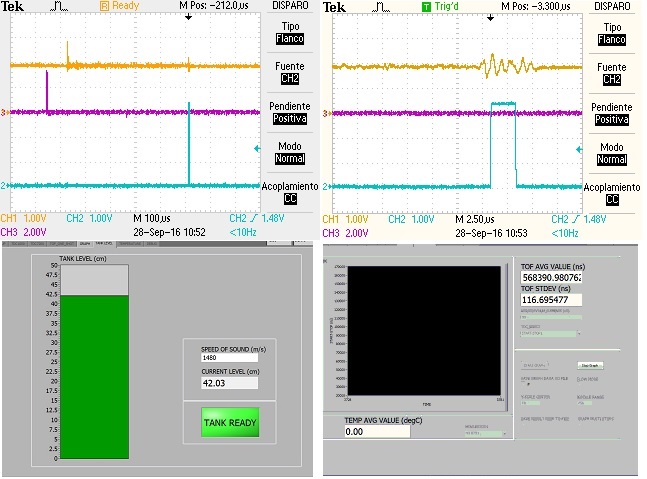

I am using the ultrasonic transducer SMD15T21R111WL with the development kit www.ti.com/.../tdc1000-c2000evm

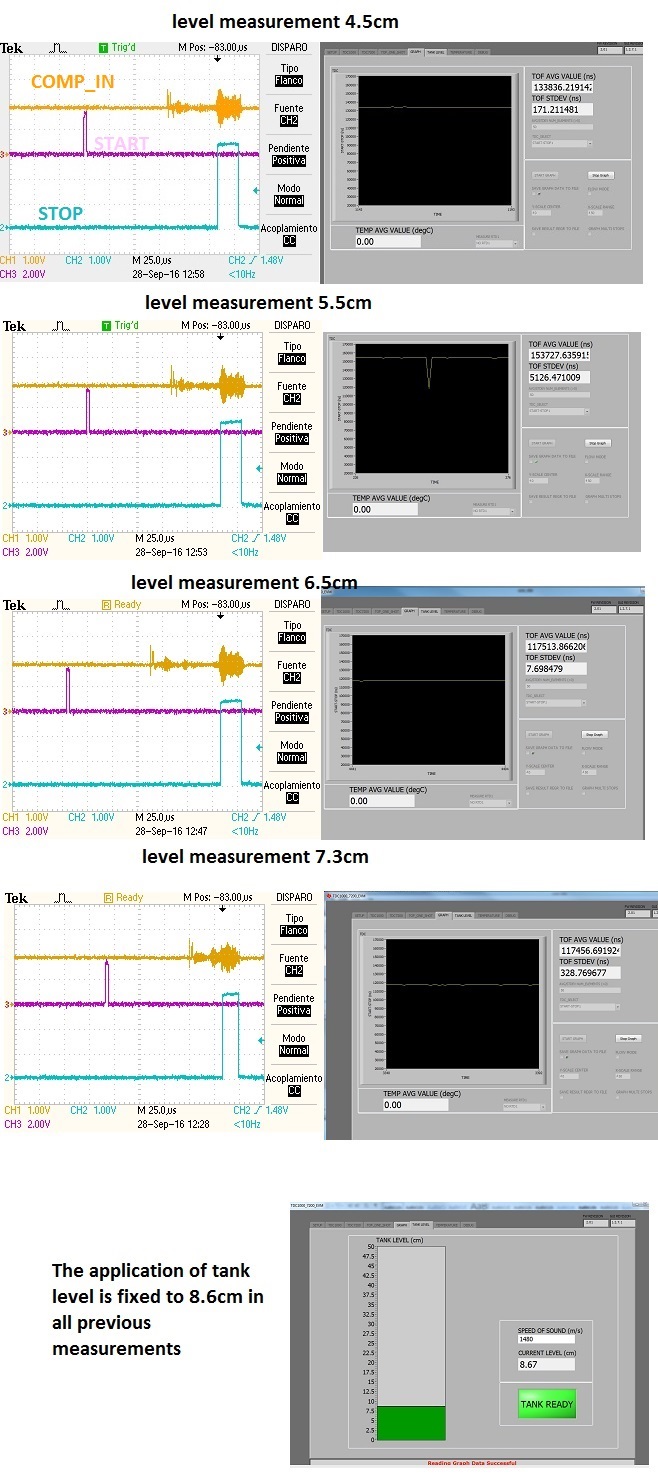

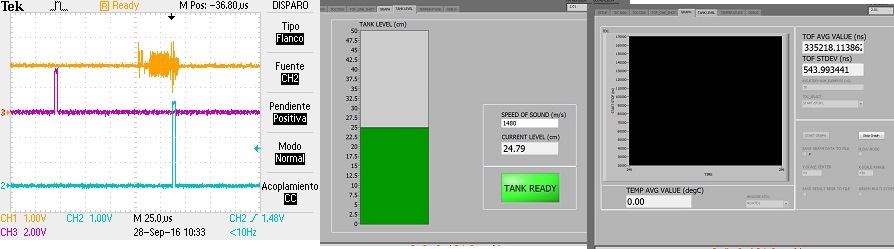

I tried it in small containers of acrylic and metal and it worked

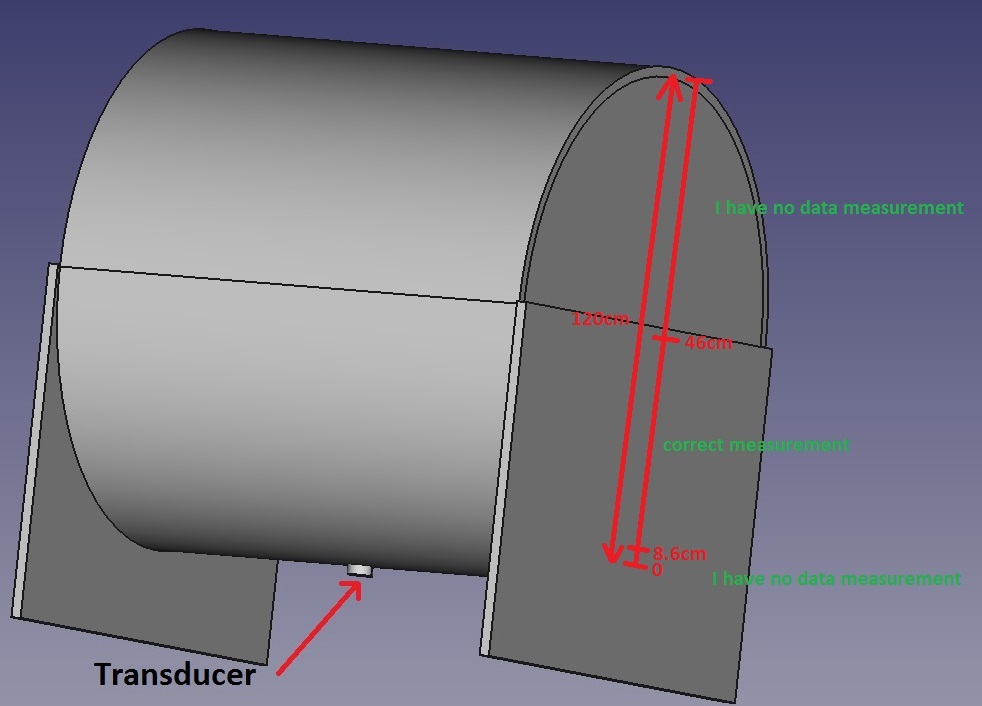

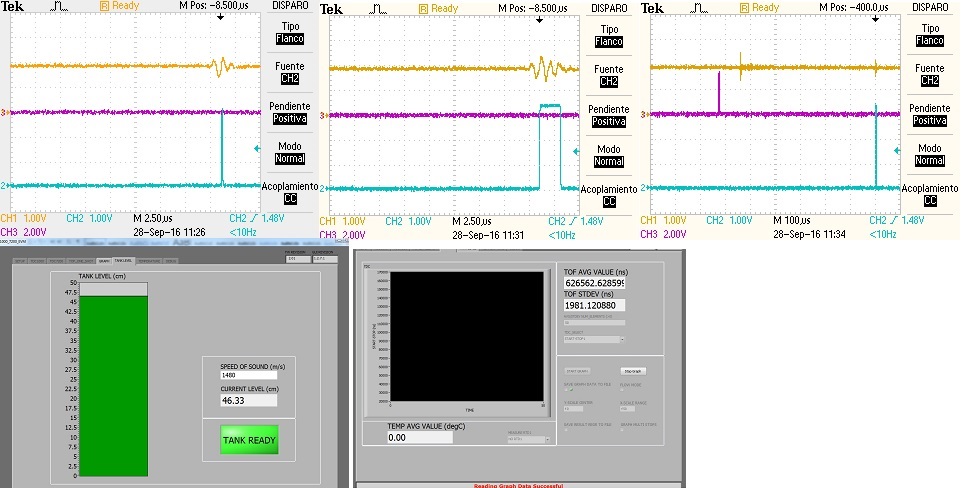

But it has not worked in large containers, my tank is a steel cylinder with a thickness of 2 and 4 mm, the cacateristicas cylinder are 85cm in diameter, 150cm long, the sensor is placed on the curved surface and the idea is to measure the level liquid (diesel), I followed the steps for installation (www.ti.com/.../snaa266a.pdf) but do not get measurement when I filled the tank, I can do to take the Transducer correct measurement, my Transducer is correct? or recommendation I can give for this type of measurement?

Based on the application note (www.ti.com/.../sniu026a.pdf) increase the voltage to 18VDC in the exitacion transducer (I have the UCC27531DBVR component, so not I could increase the voltage to 30VDC) is performed by components that had on hand, even though I failed to make a correct measurement in my Transducer mounted on the tank.

Does anyone has been able to perform measurements in conditions similar to mine with evm tdc1000-c2000evm ?..

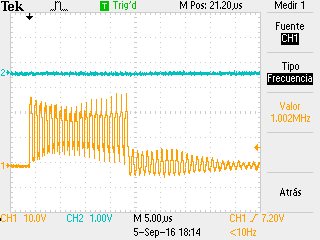

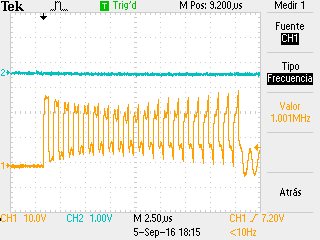

I tested with different parameters in the application NUM-TX (4,10,20,30 pulses) and ECHO_QUAL_THLD (-35, -50, -125, -220, -410, -1500mV) and still not get good results .

What is the recommendation TI?

Regards

Uriel