Other Parts Discussed in Thread: LDC1101

Hello!

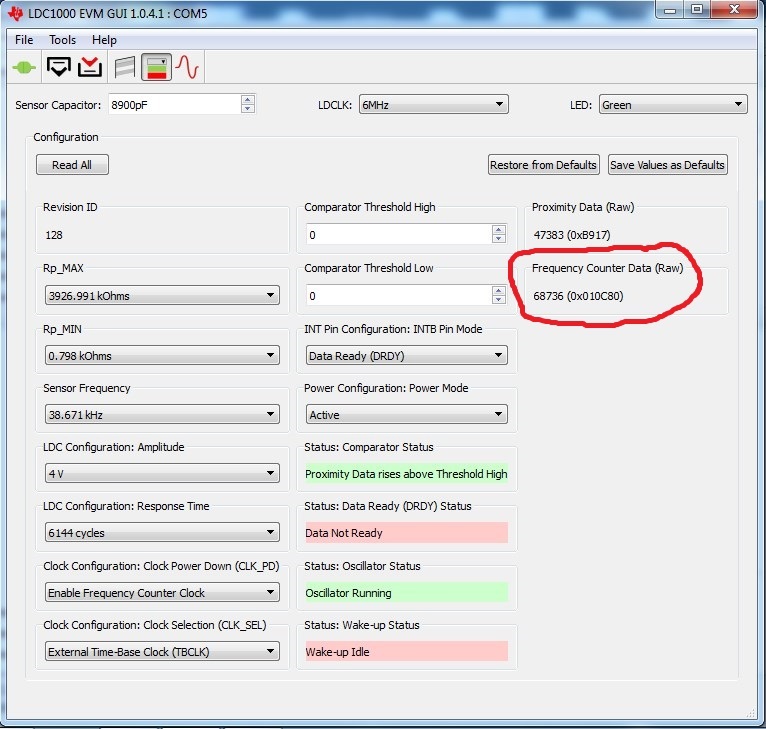

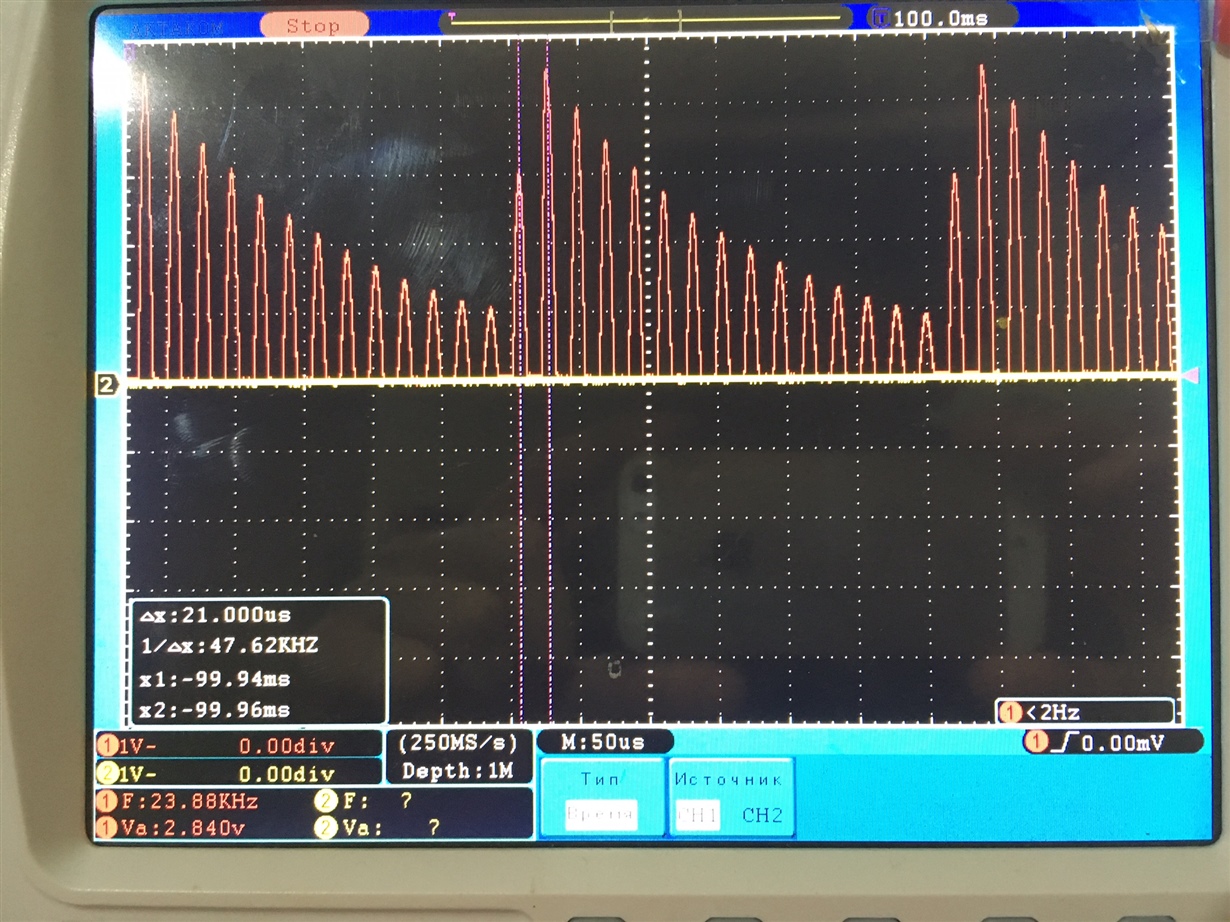

I made a sensor, about 220 turns with a 0.2 mm wire, a winding diameter of about 1.5 cm. I chose the frequency below to see the difference between ferrous metals and non-ferrous metals.

Measuring the RLC-meter separately the coil and the capacitor and received the following data:

L = 1235 μH

Resistance DCR (on a direct current) = 9,4 Ohm

C = 8.9 nF

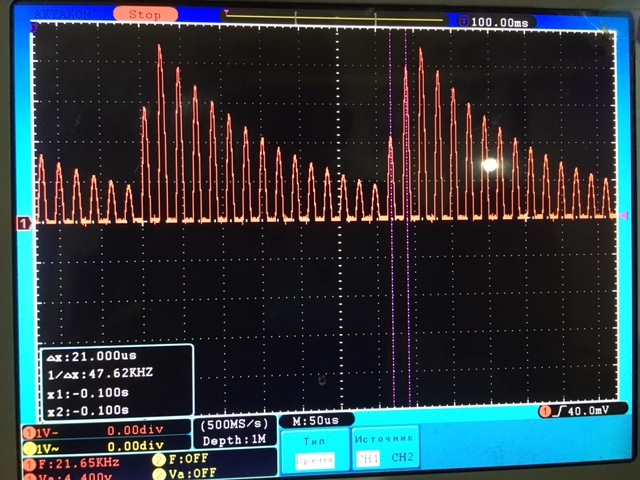

The calculated and mesured resonance frequency was about 48 kHz.

Measured at the resonance frequency, the resistance of the circuit Rp was 8 kΩ.

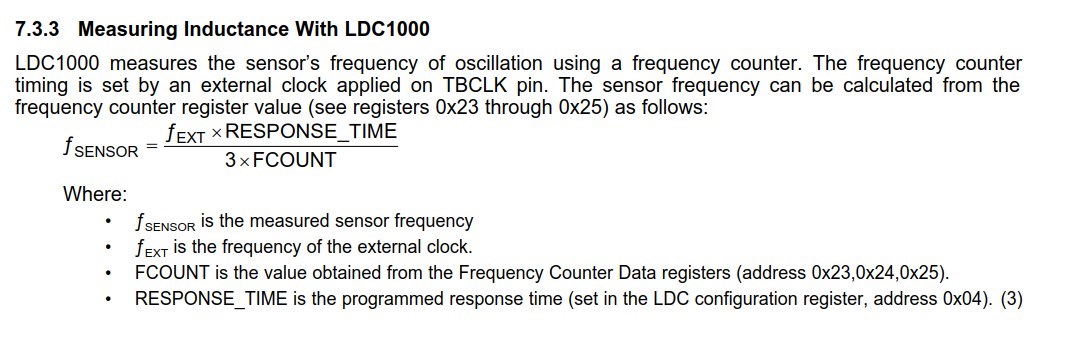

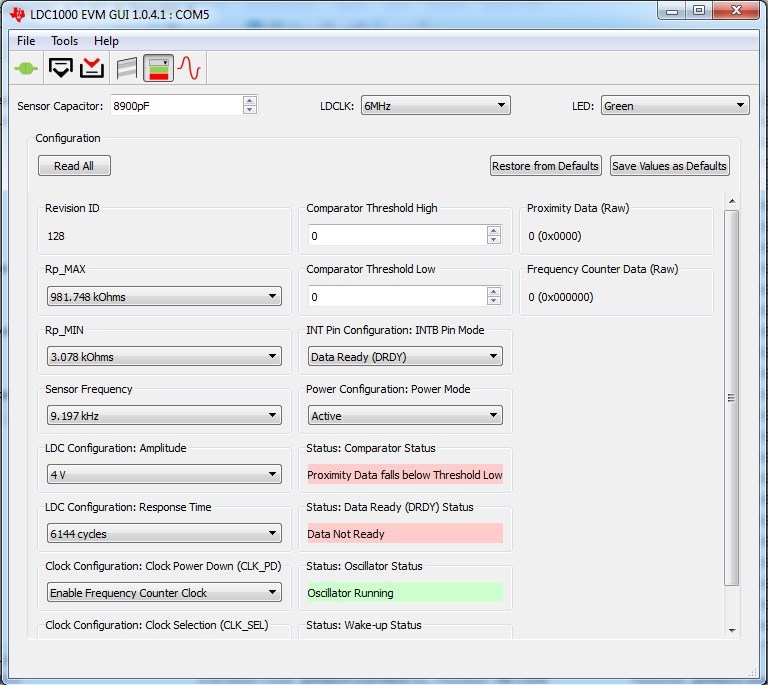

Acted according to the instruction (slyw022):

1. I broke the factory coil from the board

2. Measured L handmade coil

3. Measured C

4. Calculated and measured the resonant frequency, it was 48 kHz, which falls in the range from 5 kHz to 5 MHz

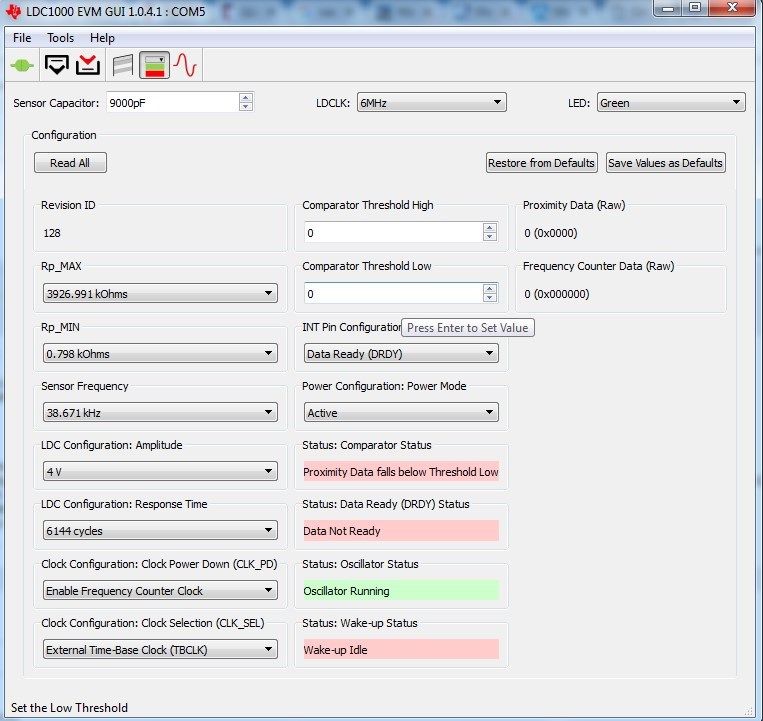

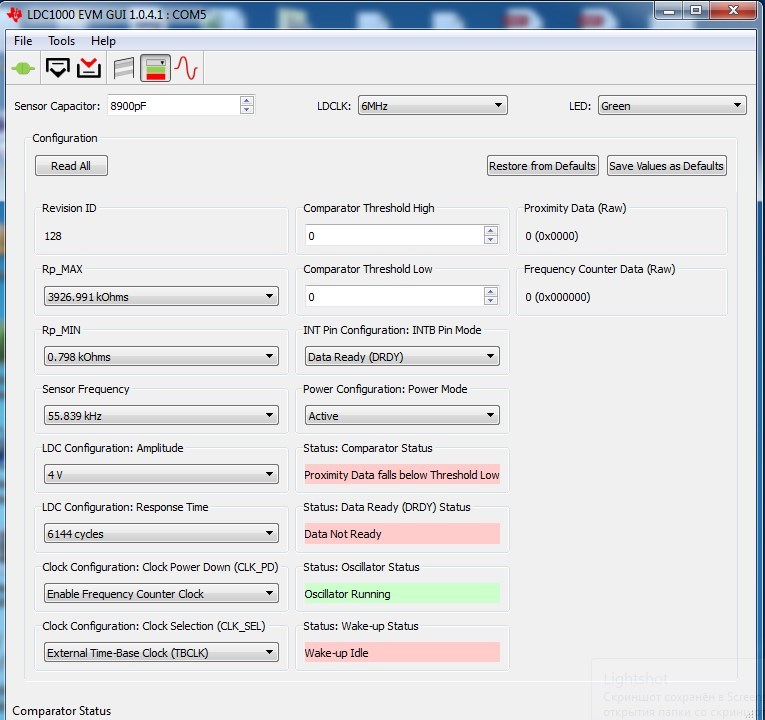

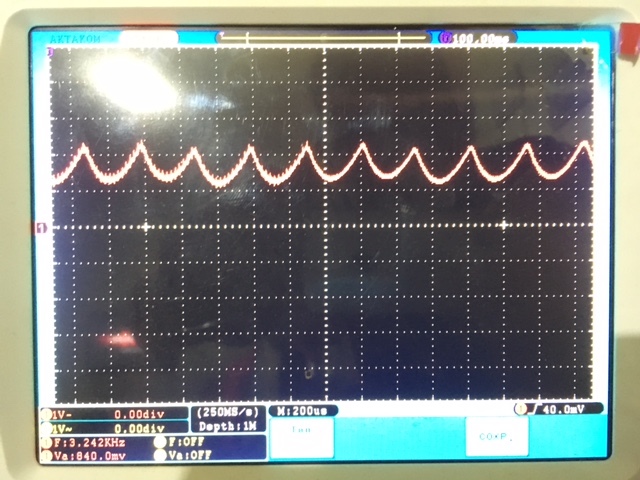

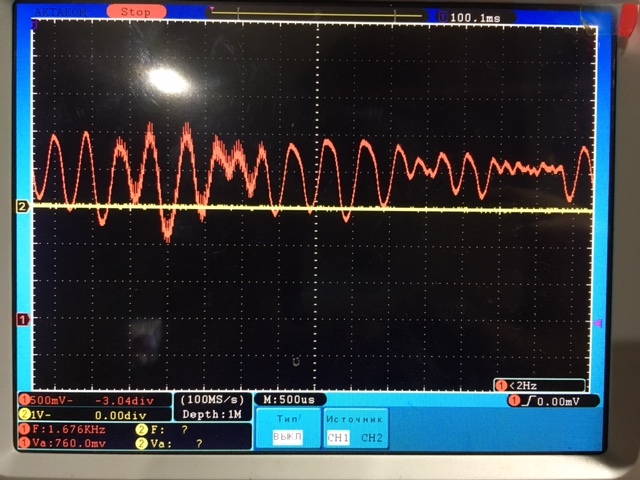

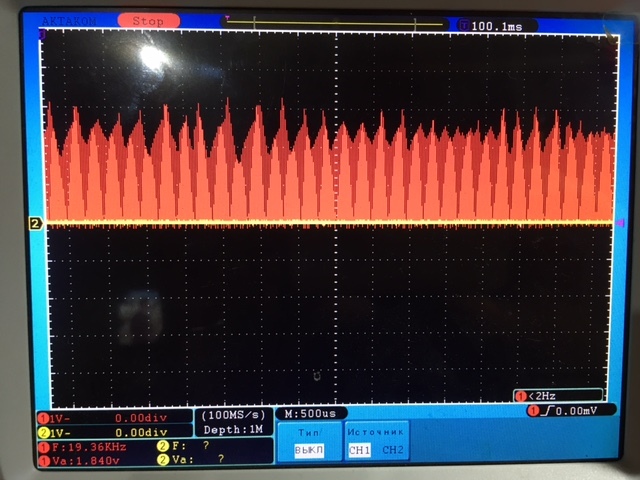

5. On the oscilloscope and the oscillator according to the instruction (method 3 in snoa936, measured Rp was 8 kΩ (Rs about 15-17 Ohm), which falls in the range from 0.798 kΩ to 3926.991 kΩ

6. Updated the capacitor readings in the program.

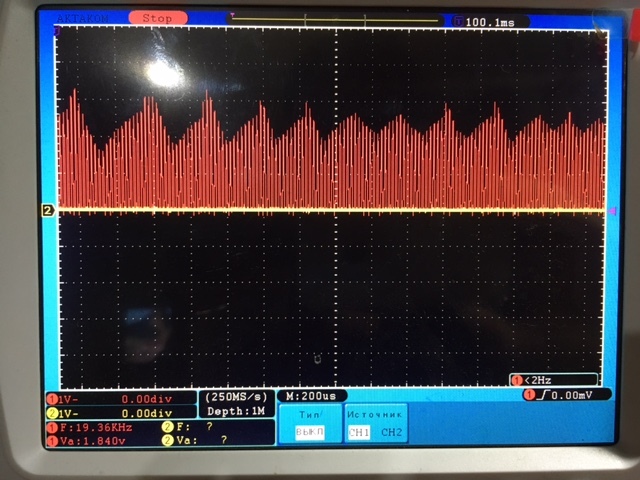

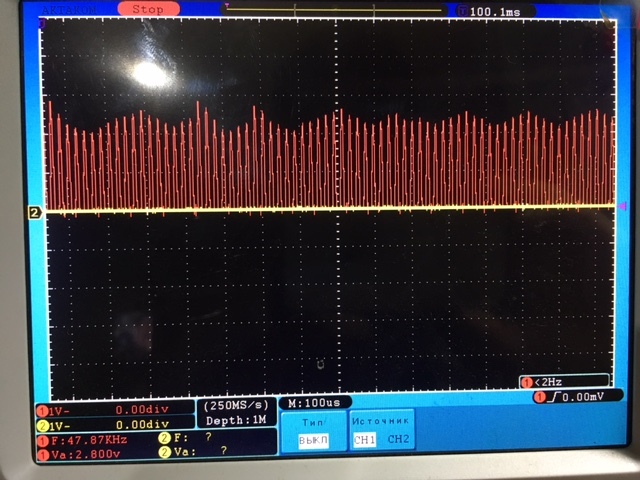

7. I chose the sensor frequency 20% lower, i.e. about 38 kHz (attached)

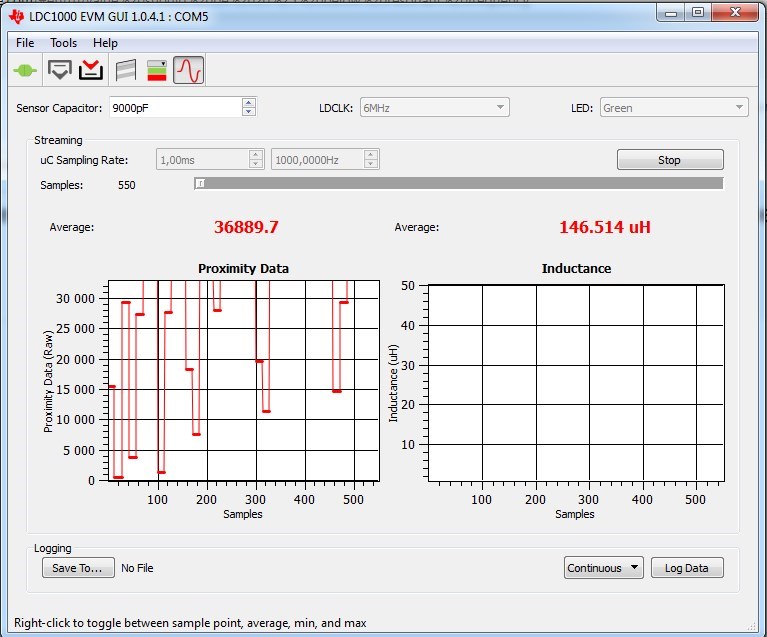

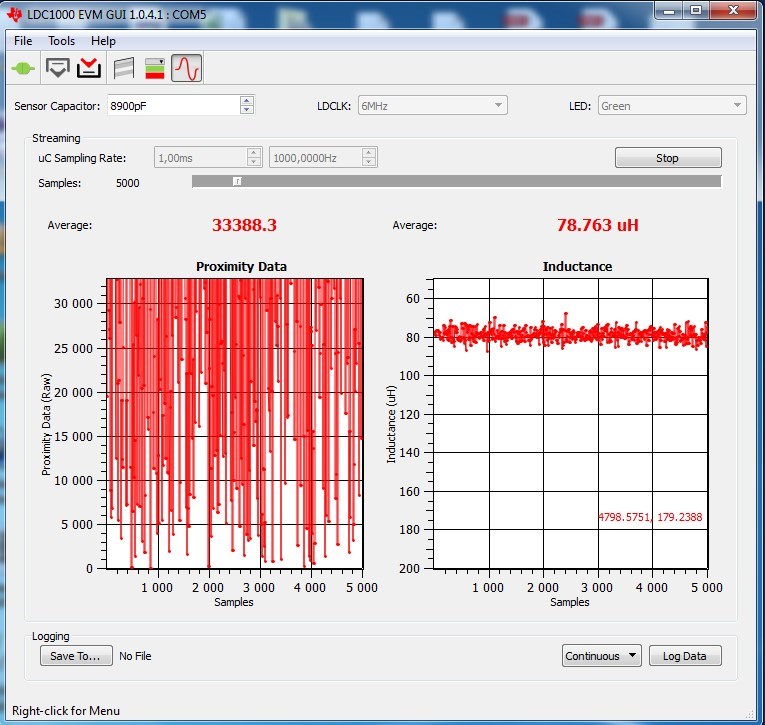

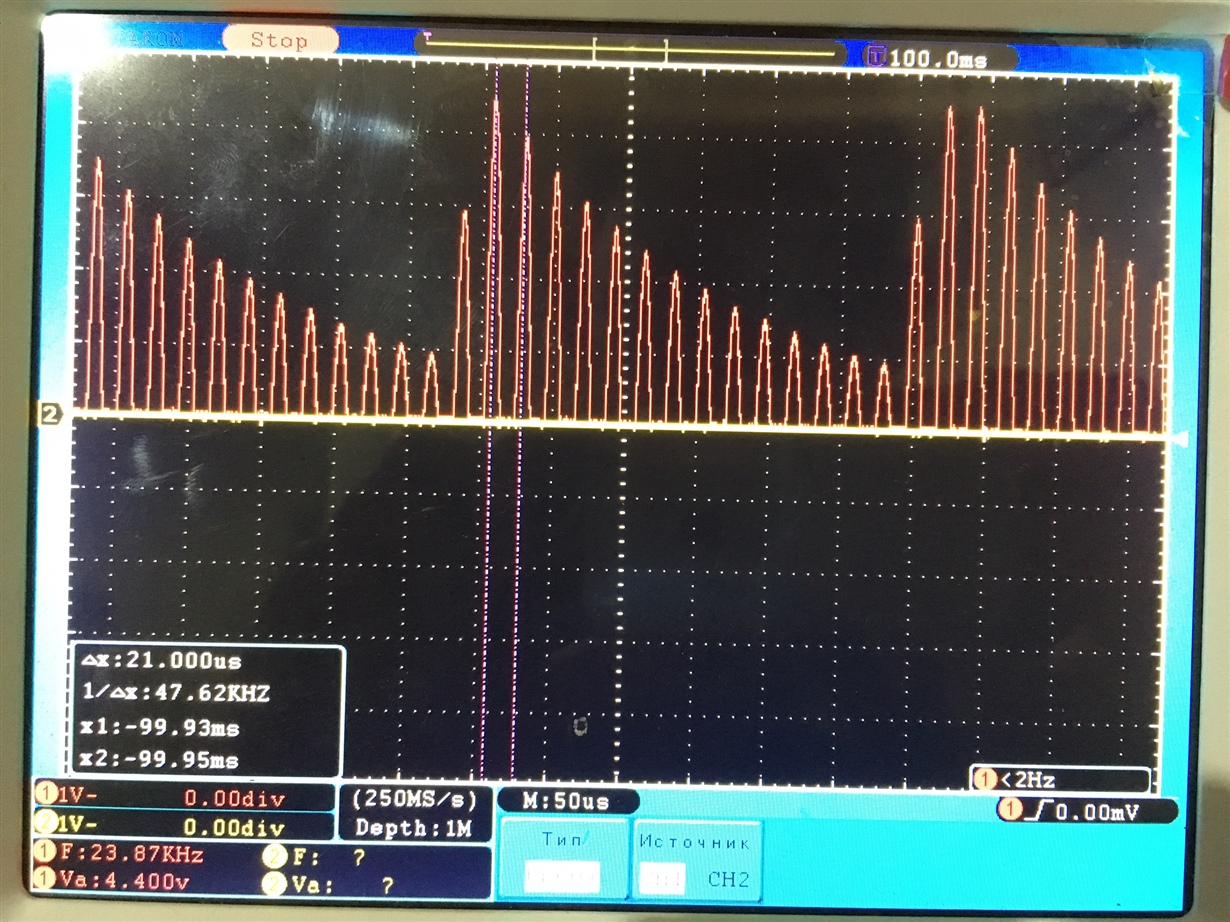

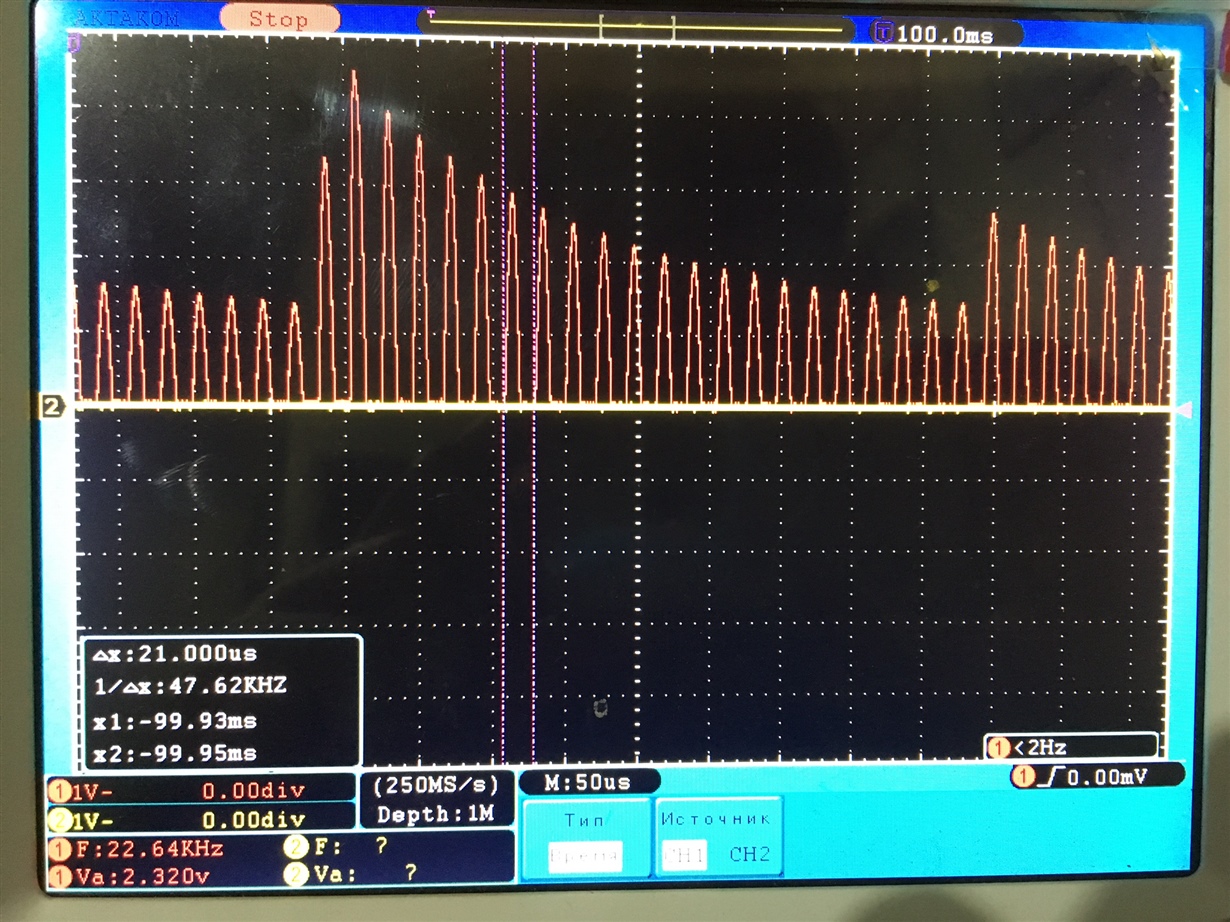

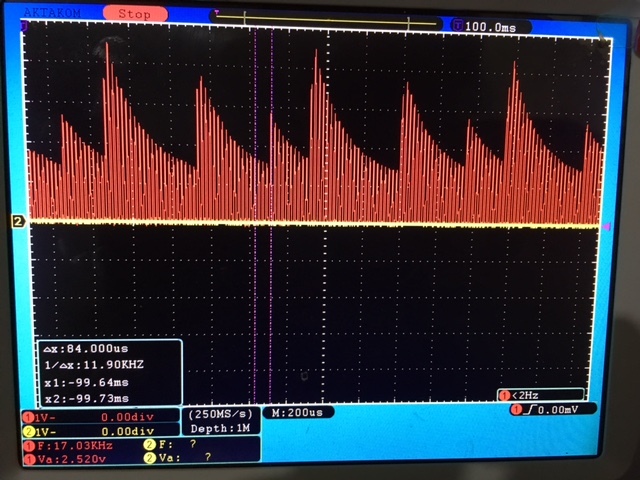

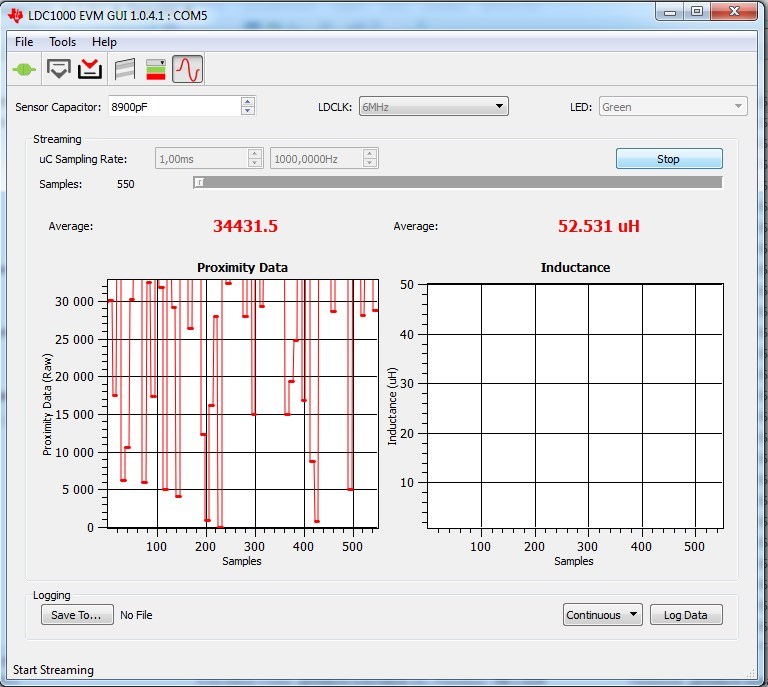

8. When I pressed "Start", then I have a proximity data that goes off scale! (see attached images)

Why does this happen and what did I do wrong?