Hello,

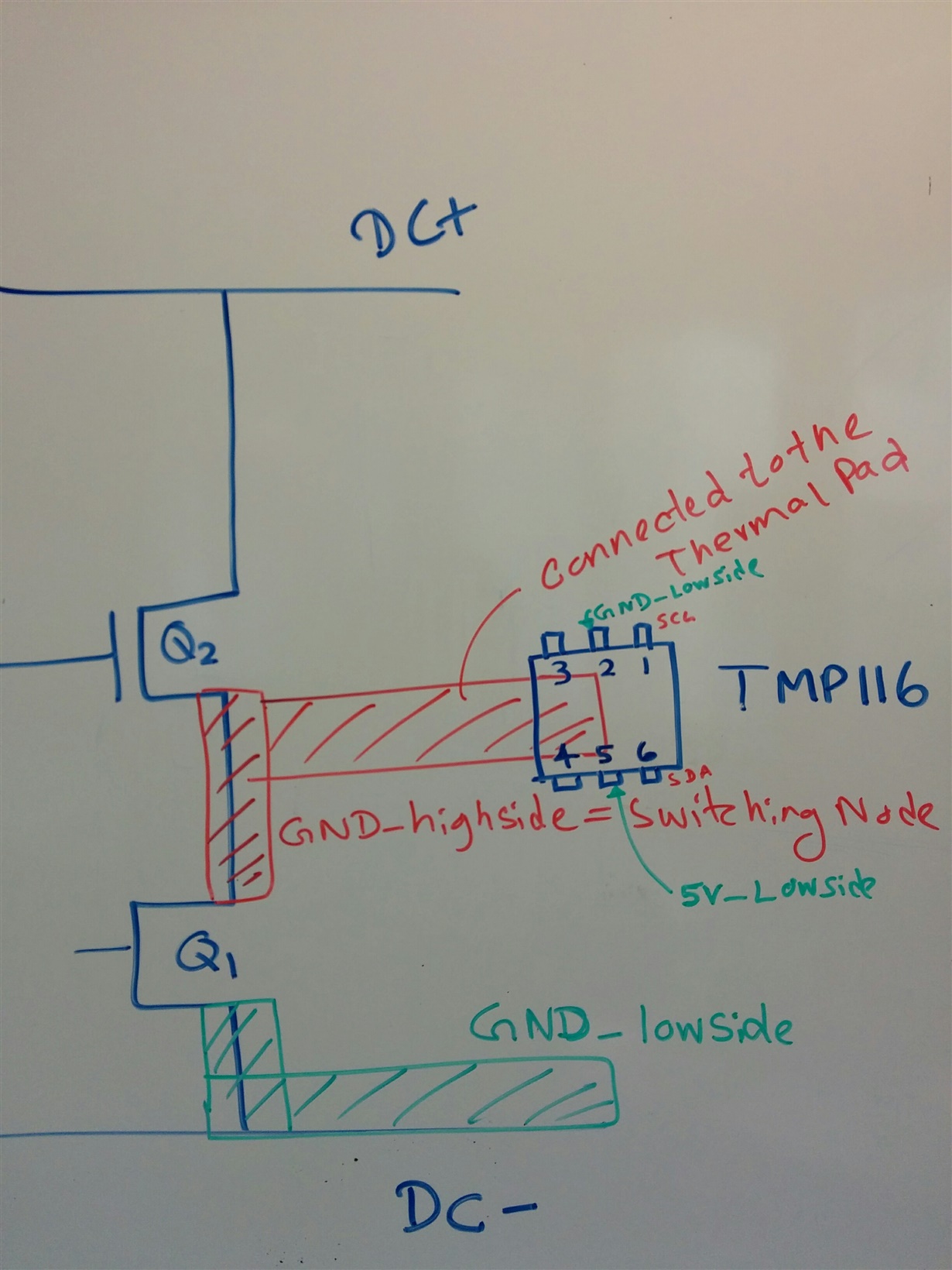

I selected TMP116 as the choice of temperature sensors for a circuit that required measuring temperatures on the PCB copper pads at three different points.

So I soldered the thermal pad of the IC to respective PCB copper pads.

However, I found that two of them keep getting damaged.

After lot of work I found that the TMP116 pad is not electrically isolated although it claims in the datasheet this is the case (see the attached figures). It says there is a non-conductive die-adhesive between the pad and the die.

I found that when the thermal pad is positively biased with respect to the ground pin, the path breaks when you go above 2-3 volts and start conducting with a diode behavior.

I have tested the IC on my PCB to figure out the problem.

Then, to make sure, I used two new ICs and had them separately biased as I mentioned above and see what happens (without the PCB). Both of them starts a being conductive after the bias goes above 2-3 volts. the current starts around 100 mA and goes up to 500 mA around 3V.

Could you please tell me why the pad behaves this way (showing no isolation) and if if TI has used TMP 116 is such situations?

Thank you very much.

-Nirmana Perera