Hi Team,

The customer is experiencing below issue and needs your help.

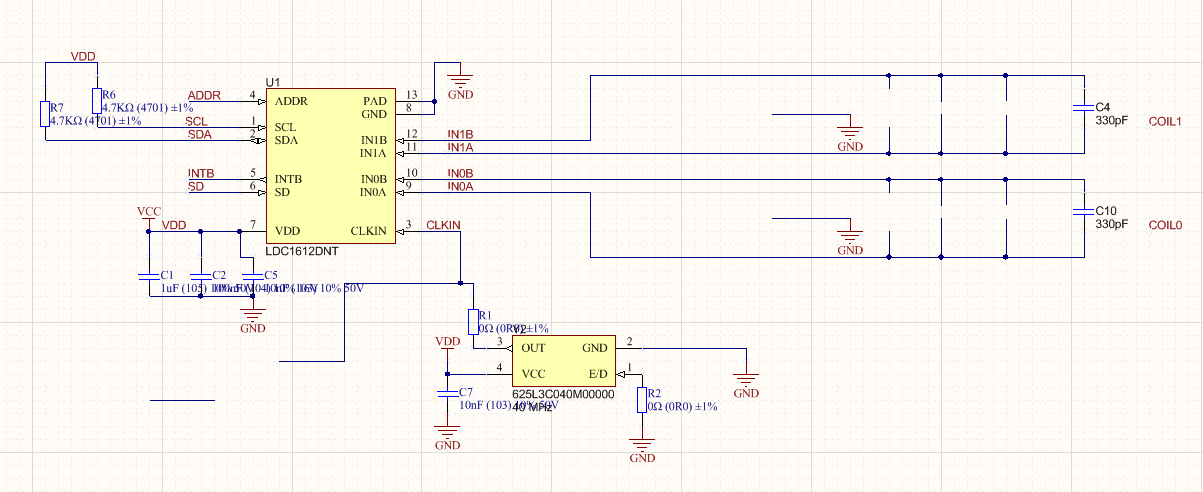

He uses LDC1612, and the drawing used is the reference board of TI. He fixed the distance between the test object and the LDC1612 coil, and placed it in a high and low temperature box for cyclic testing. An output value we measured at room temperature is stable, then after the system has passed a high temperature of 80 degrees for a few hours, then reduce the temperature to room temperature. After stabilizing at room temperature for a sufficient time, he found that the stable output value afterwards had more than 100 drift changes before high-temperature baking. He has done the above experiments with both internal and external crystals, and found that there is a large deviation (at a distance of 9mm, the reading drifts by more than 100).

He would like to know is it caused by LDC1612 or other reasons?

The key 330pF capacitor he used NP0 high stability capacitor. He hopes that the system will repeat the cycle from -40 degrees to 80 degrees. Under the same test object, test distance, and the same temperature, the test readings will be consistent. Can this goal be achieved?

Thanks,

Annie