Other Parts Discussed in Thread: MMWAVEICBOOST,

Hi there,

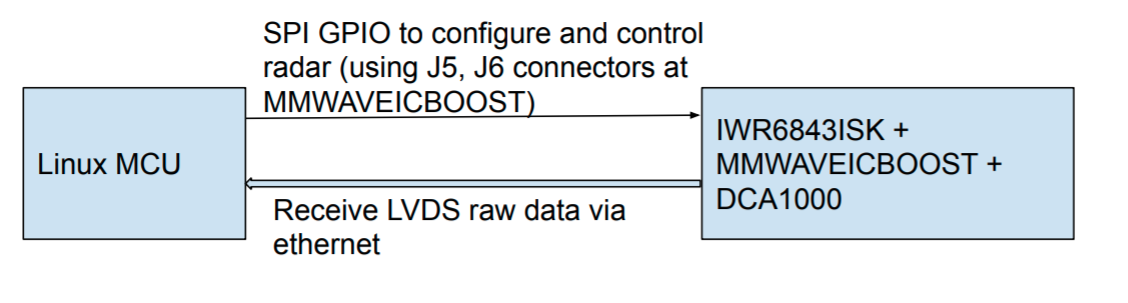

We would like to configure and control the IWR6843ISK radar from external MCU via GPIO connectors (Launchpad J5 and J6 on MMWAVEICBOOST). Could you please suggest what modifications should we make to Demo project for it to work? Specifically, I have the following questions:

- In my understanding, the default setup utilizes UART protocol over USB connector with FTDI drivers to configure and control radar via serial commands. In the modified setup with SPI GPIO, would we need any driver for radar to understand the commands?

- Would we need to change the commands for SPI communication?

- From my research into this modification, I believe we'll need to use the SPI for "External MCU interface" in the image shown below and this SPI connects to SPI pins on LaunchPad connectors J5, J6. Is that correct?

Thank you

Arvind