Hi there!

We are currently evaluating the awesome TPS8804 smoke detector AFE.

And I noticed that there is a SLC interface which looks really handy, and offers a power-line-communication-like interface.

We've noticed that SLC seems to be a well adopted physical layer in the fire alarm industry, but without a unified standard. (and often time closed protocol)

We would like a develop a home automation & fire security system using this SLC interface.

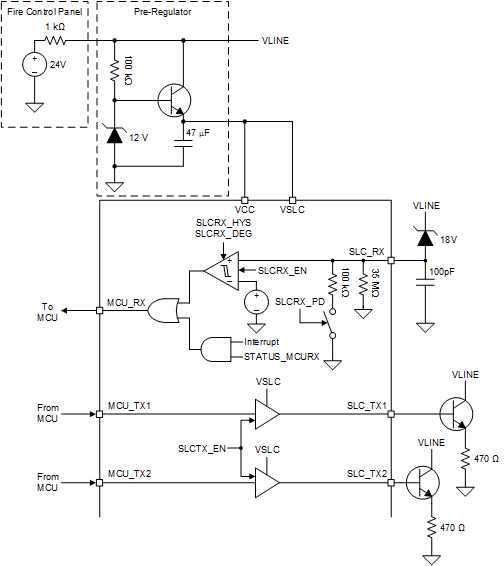

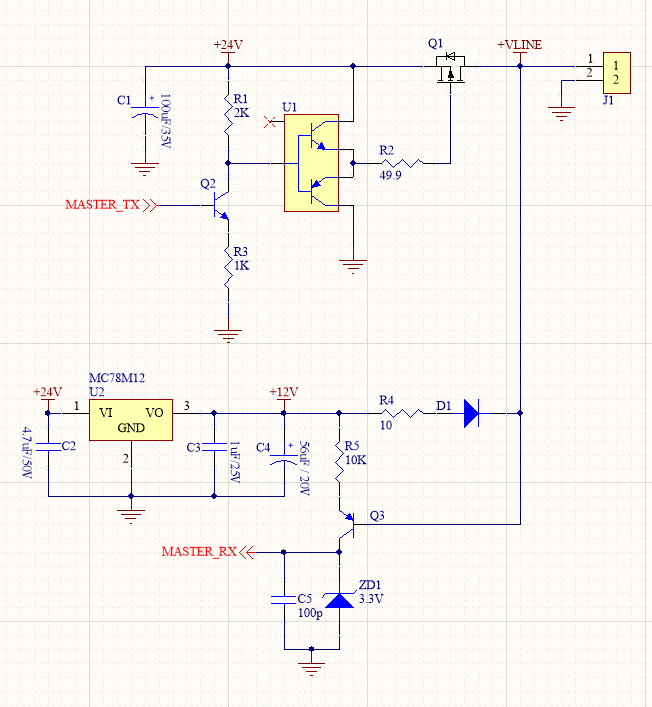

Wondering if there is a SLC reference design or guideline.

Especially the hardware implementation of master side of the power bus, that is, the one who talks to TPS8804 and other SLC slaves.

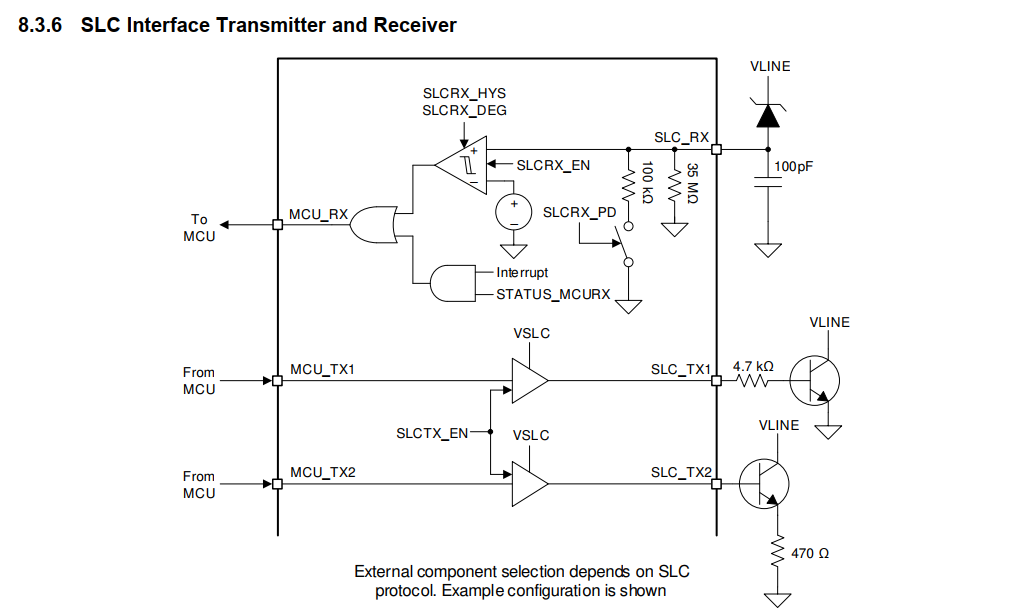

Here is a screen shot from TPS8804 datasheet.

Thank you all in advanced!

Zt.