Hello,

We are using HDC2080 sensor in one of our design and we have observed misbehaviour of the sensor. The sensor reads 100% humidity continuously and recovers only after a power reset. And this is observed soon after power on of the device and also during mid of testing.

Below are other details.

1) The actual humidity was around 16%, where as the sensor read 100%

2) Also temperature offset of 2-3 degrees observed.(Temperature reading was 2 degrees higher than expected)

3)After the power reset of the board,the sensor started reading the optimum value of humidity and temperature.

4) This was observed in 2 of our products. One was kept in temperature chamber at 40 degrees and one was in room temperature

During this phase of misbehaviour we have conducted a few experiments and captured few observations. The details are explained below

1) Kept the PCB in most ventilated place.

2) Place the finger on the sensor for some time

3) Blew hot air on the sensor area. After this process only temperature reading showed higher value but the humidity was still 100%

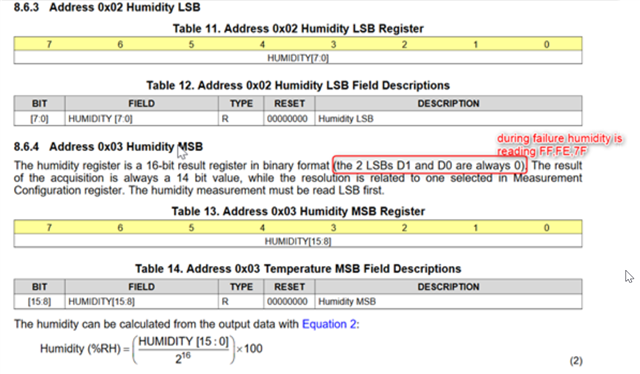

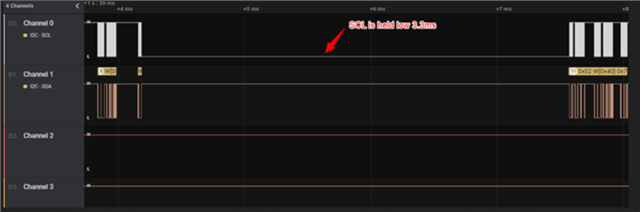

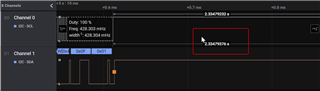

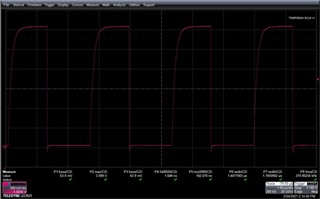

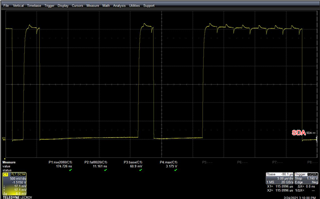

4) We are using I2C as communication interface, so we analysed the communication data as well. We see that,according to data sheet, the values in the 2 LSBs D0 and D1 needs to be 0 in humidity register.This is not met

5) Finally we did a power reset, the sensor started working normally.

All the necessary pictures have been shared as attachment

Please let us know if you need any other information. Can somebody help us solve the issue at soonest as we are moving to C sample design with this sensor already.