Other Parts Discussed in Thread: LDC1101, TDC7201, LDC1001

Hello There,

as described in SNOA941A I would like to use TDC7200 with LDC1101 in DRDY RP+L mode for time measurement between DRDY assertion.

Topic A:

For best possible accuracy I read in manual for TDC7200 SNAS947D in section 8.4.5 START and STOP Edge Polarity that ideally:

- ... same edge polarity for the START and STOP input is highly recommended. - that is easily achievable since LDC has always pulse (rising and falling edge) for START and even for STOPs in DRDY mode.

- it's strongly recommended to choose for the START and STOP signal the "rising edge". - unfortunately this is not a choice in DRDY mode. Time (conversion) is measured always between falling edges.

I would like to know recommendation for this configuration and some estimate of INaccuracy.

Q1: What is degrease of accuracy when reading timestamp between falling edges instead of rising edges?

Q2: Would you recommend to use some kind of invertor (SN74LVC...) connection to invert pulses of DRDY assertion from LDC1101 to get recommended rising edges or it would bring more inaccuracy than actual measurement of falling edges just by TDC7200?

Topic B:

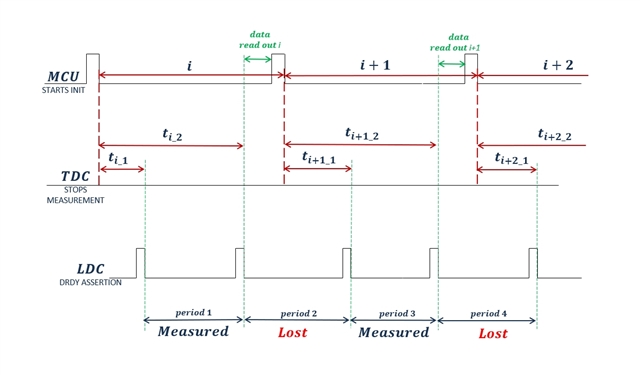

Also based on measurement nature of TDC and LDC in DRDY mode, it is unclear how to set TDC in order to continuously get conversion results from LDC1101. Once one conversion period is completed ideally the TDC should start immediately to measure next time between DRDY assertions in order not to loose any conversion period of LDC which it results in lost of every other conversion period.

Q3: How to achieve continuous conversion without loosing any single measurement period?

Q4: Can TDC continue to measure for example second stop while first measurement data are being read by MCU?

Q5: How it then deals with calibration measurements? (same calibration used for two measurements)

Using two stops may work in matter: While a 1st-stop-data are being read a 2nd-stop-data may be measured and then it may swap for reading 2nd-stop-data and measuring 1st-stop-data again. I do see here a problem that it will have to eventually loose one conversion of LDC in order to reset the TDC. Am I correct or there is a way to avoid it? Using two channel TDC7201 or so...

Thank you.

Best Regards,

Michael