Other Parts Discussed in Thread: LDC0851, LDC0851EVM, LDC1312

Hello Team,

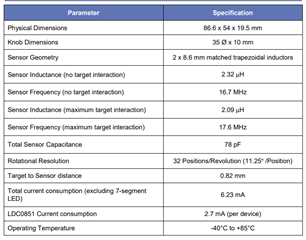

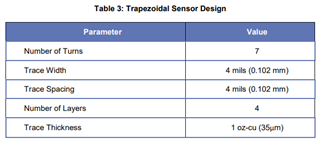

we are developing inductive encoder using reference design of TIDA-00828., while referring all reference documents I found all documents related to sensor design . but PCB layout and Gerber file of target design is not present. can you share design files related to target design for 32 position.

Regards,

Sayali