Other Parts Discussed in Thread: TDC7200, TPL0202-10

Hi Team,

I have a couple of questions about the design reference TIDA-00663.

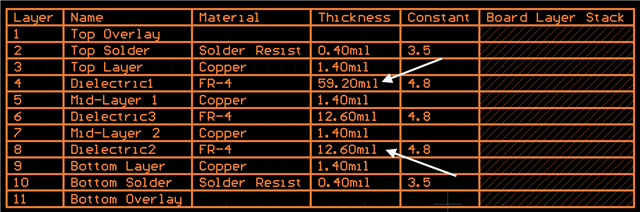

1) I am trying to build the TIDA-00663. However, the manufacturer of the PCB noticed that the stack-up could have some problems. In particular, there could be a bow and twist due to the high difference between the thicknesses of layer 4 and layer 8. Is the stack-up (with the order defined by the “Layer” column) in the Gerber file correct ? In this case, how do you suggest to solve this problem?

2) Is the entire TIDA-00663 design expected to have an experimentally 1 cm resolution, even considering that the rise time of the pulsed laser "SPL LL90_3" is in the order of 10 ns?

Thank you in advance.

Regards

Giovanni