Other Parts Discussed in Thread: MSP430F5529, DRV8343-Q1, TMS320F28035

Hi,

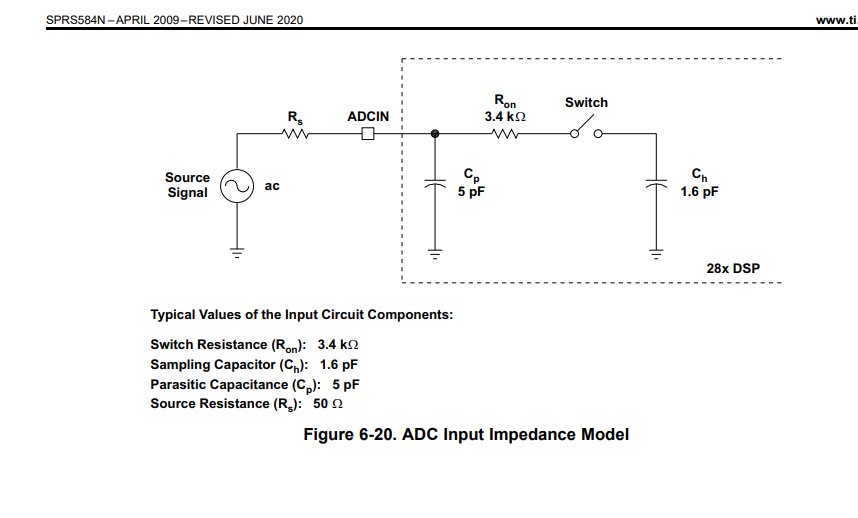

I have a question on RC values for TMS320F28035 MCU low-pass filtering used in TIDA-060030 board. The current sensing pins, ISEN_A, ISEN_B, ISEN_C use R=56 ohms and C=2200pF, which leads to very fast time constant, about 120 ns. I check the datasheet of TMS320F28035, ADC conversion time is 217 ns in Table 3-1. Assuming 1% error, 5 times RC equals to 600 ns, which is larger than the ADC conversion time of 217 ns. I am wondering whether the C of 2200 pF is too large in this EVM board design. Please advise.

Another question is which frequency the TIDA-060030 design try to filter? For 45KHz PWM, it seems to me that above 45KHz frequency should be filtered. If this is the case, RC should be about 1/(5*f_sw) = 4.5 us. From this perspective, both R and C should be larger. My understanding is that C value should be larger than C_SAMPLE inside the MCU so that C_SAMPLE can be fully charged. Does the MCU has a maximum RC value limit? If yes, what is it?

Thus, I am confused. I will appreciate your insight in RC filter design for ADC.

Thanks,

John