Other Parts Discussed in Thread: MSP430FR2355, DRV8350R, DRV8323, DRV8350, DRV8353

Hello TI Helpers,

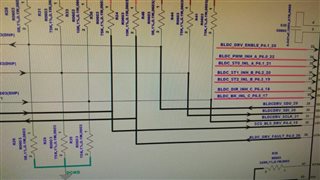

I am using TIDA-010056. In which I have not connected BLDC motor to the hardware. I have also not connected Hall Sensors of BLDC motor to TIDA-010056. Just I want to check only waveforms on MOSFET side in free running mode ( without connecting BLDC motor and Hall Sensors ).

So what things I have to change in CCS programe code (given by TI for TIDA-010056) ?

If you give updated program ( without connecting hall sensors and BLDC) it will be great help.

Thank you in advance.