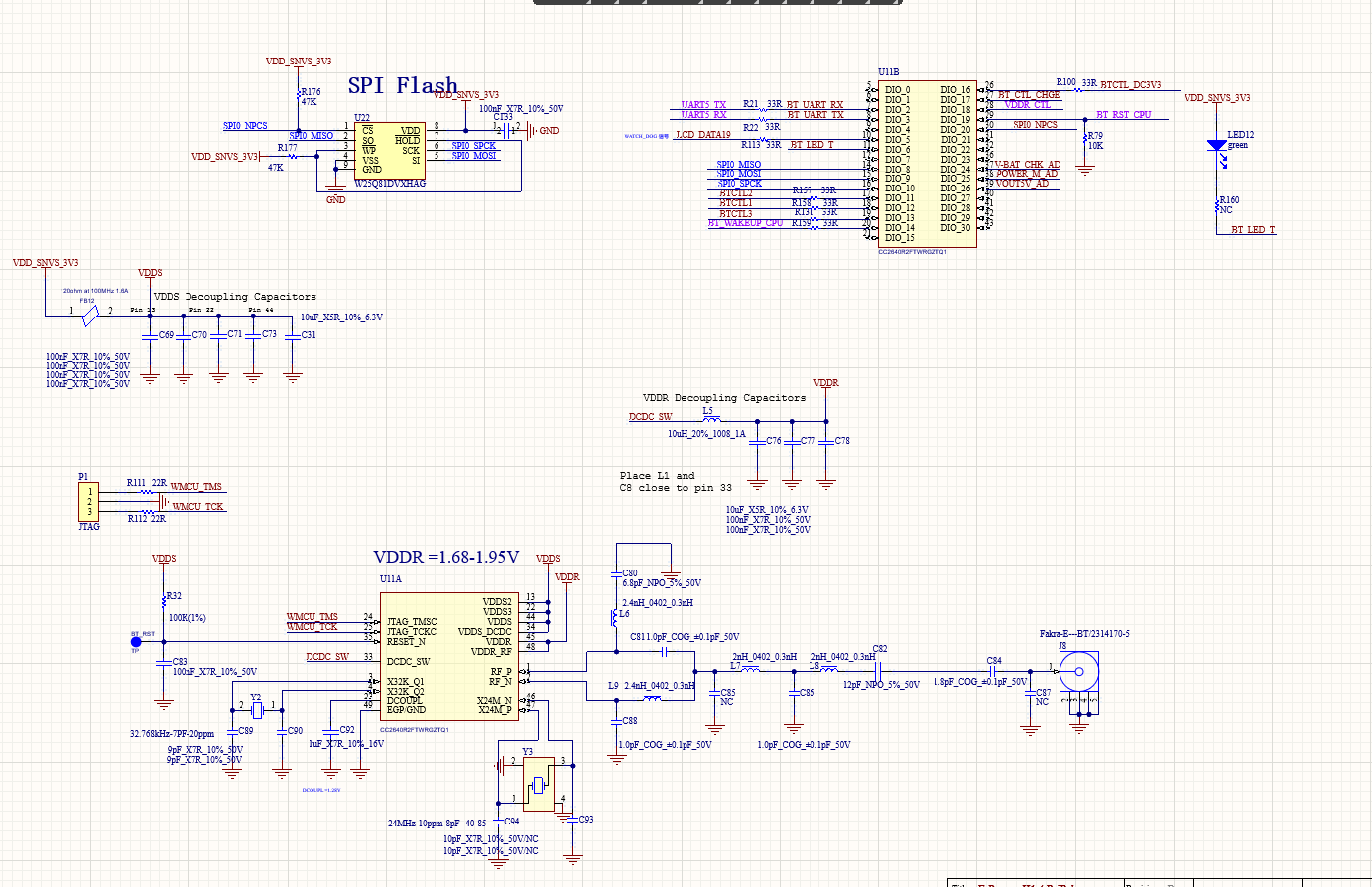

Other Parts Discussed in Thread: CC2640,

1. When the problem occurs, the main power supply voltage of Bluetooth is 2.327V;

2. Now this problem can recur stably. After the equipment on the car has a problem, we have recurred this problem on other equipment, which seems to be a common problem.

The method of reproduction is as follows:

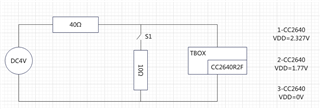

• The duplicated logic is to simulate the ignition of the truck battery when the power supply is insufficient. The test circuit diagram is as follows:

• TBOX is started by Bluetooth. The power supply voltage of TBOX is 4.0V. A 40 ohm resistor is connected in series on the circuit, and a 10 ohm resistor and S1 switch are connected in parallel between the positive and negative poles. S1 switch is off by default.

• Step 1: Use the switching power supply to power on TBOX, and disconnect S1. At this time, the main power voltage of CC2640R2F is 2.327V, and the measured voltage between SWD and GND of CC2640 CJtag is 2.327V;

• Step 2: Close S1 switch, measure that the voltage between SWD and GND of CC2640 CJtag is 1.77V, then disconnect S1, measure that the voltage between SWD and GND of CC2640 CJtag is still 1.77V, then quickly close and disconnect S1 switch, about 500-1000 times, the voltage between SWD and GND will still be 0V, and then whatever operation is done later, the voltage output of SWD and GND of CC2640 CJtag will be 0V, It is not enough to increase the power supply voltage. It can only be restored after resetting or powering off.

3. When the voltage output of both the SWD and GND of the CC2640 CJtag is 0V, the crystal oscillator does not start to vibrate, but this problem has been repeated on several devices, and it is uncertain whether it is the crystal oscillator.

When CC2640R2F is started, is there a process of switching from the internal crystal oscillator to the external crystal oscillator? Can we grab the card at which step?

Whether the other three requirements can be realized:

1. Does CC2640R2F support switching from external crystal oscillator to internal crystal oscillator during operation?

2. Does CC2640R2F support the status query of whether the external crystal oscillator operates normally during operation?

3. During the test, we found that the first line after the main increased the delay, which reduced the frequency of problem recurrence. After the modification, it took about 1500 times to reproduce. Can this delay be advanced to the assembly code that started?

To add, the SDK of CC2640R2F is 4.44.0.10