Hi,

We made a circuit for reading temperature and GSR. We faced some problems using the NFC reader and mobile application which we made.

1. The NFC reader didn't read our circuit.

We wrote source code at Matlab based on your RF430FRL152H Gui interface, but it didn't work. here's our code.

Pls, figure it out the code problem.

command1 = '0108000304FF0000'; %TRF7970AEVM

command2 = '0109000304F0000000';

command3 = '0109000304F1FF0000';

command4 = '010C00030410002101020000'; %Register write request.

%% Skin conductivity + temp sensing

command5 = '011300030418022102001011000000FFFF0000'; %block 2 Oversampling rate 128

command8 = '01130003041802210001000601020101400000'; %block 0 % ADC1, ADC2 on , Freqency: Two times per second, number of passes: 2 (for infinite sampling), using thermistor (p33~p37)

command9 = '010B000304180220090000'; % samples all sensors Request mode.[sample data]

2. NFC chip doesn't work after reading mobile application.

Because of the problem at NFC reader, we used the Android mobile application which we made for reading temperature and GSR data.

At first, everything was good, after several measurements using a smartphone, it didn't work.

Therefore we changed the NFC chip, it fixed but it was not working soon.

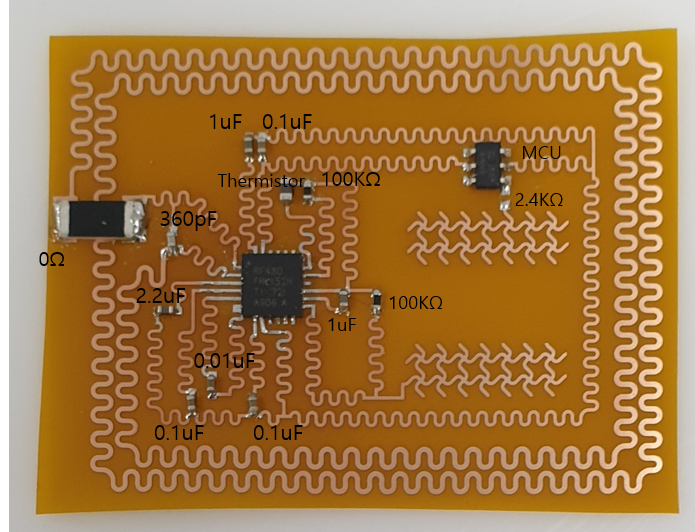

We guess something wrong in our circuit. Here's our circuit. Could you tell us the reason why the NFC chip broke too fast?

Thanks

JooHo