Other Parts Discussed in Thread: CC1310

Setup:

Win 10 PC, Code Composer Studio Version: 10.1.1.00004, Sensor Controller Studio 2.7.0.155, Node and Concentrator project, using CC1310 as node and CC1352 as concentrator.

Success:

I had good success running TI generated code on 3 CC1310 nodes and 1 concentrator, with one ADC channel being sampled both from CCS, and from SCS. I was even to add 2 more ADC channels and successfully test (Task Test) the added ADC sampling code.

Failure:

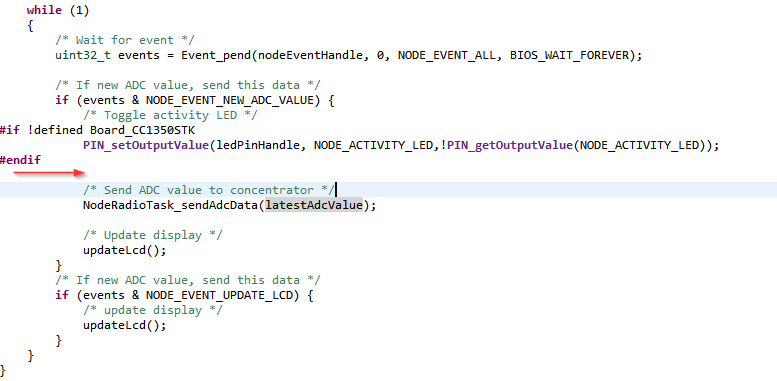

Now I have problems trying to compile the code generated from SCS in CCS once I added 2 more ADC channels.

I'm just digging into the Sensor Controller Studio for the first time, and I'm stuck and I need some help figuring out why my SCS projects runs fine (I can see ADC values changing correctly) in SCS but when the same code is generated for Code Composer Studio, I get errors in the SceAdc.c file. I don't see anything in the scif_how_to_use.html about the SceAdc.c nor is there anythng in the node readme.md file about the SceAdc file, so I'm not sure where to start.

I'm not a C programmer by trade, but I have done a number of projects involving both hardware and software (a lot of assembly) design, but this is just a little beyond my reach.

Thanks,

Tim