I’ve been asked to look at a Bluetooth issue with a Murata device (LBEP5CLWTC-631 (Type WT) ) using a TI WL1831.

Sometime ago commands were added to the default BTS start-up script in order to limit the transmit power to avoid the extra certification needed for a device running at the higher power settings.

The command sequence ended with the following command with a comment in a email suggesting this is needed to latch the new power settings.

Send_HCI_VS_DRPb_Enable_RF_Calibration_Enhanced 0xFDFB, 0x00, 0x00000800, 0x01

Wait_HCI_Command_Complete_VS_DRPb_Enable_RF_Calibration_Enhanced_Event 5000, 0x00, 0xfdfb, 0x00

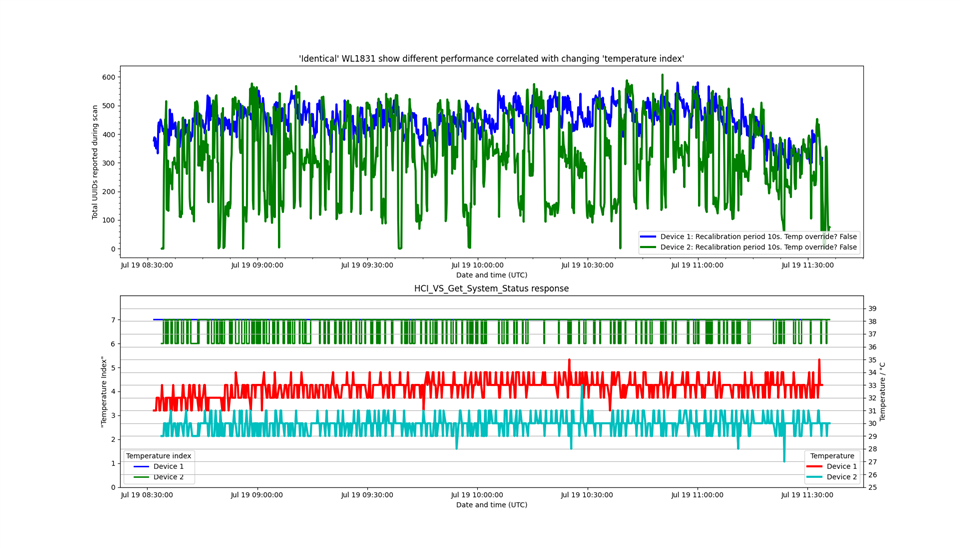

Recently while working on a new facility we noticed that every five minutes the number of devices seen by a WL1831 could change drastically. Sometimes the number would be reduced (on occasion to none) sometimes it would recover and sometime any change would be modest, what was common was the changes happened according to a 5 minute clock cycle. Looking at the documentation for Send_HCI_VS_DRPb_Enable_RF_Calibration_Enhanced we saw the periodic calibration defaults to running every five minutes.

We changed the periodic calibration frequency and saw the fault frequency changing from five minutes to the new value we supplied.

So we are confident that this is linked to the source of the errors we are seeing, we added this command just after the first.

Send_HCI_VS_DRPb_Enable_RF_Calibration_Enhanced 0xFDFB, 0x01,0xff, 0x00000000, 0x01

Wait_HCI_Command_Complete_VS_DRPb_Enable_RF_Calibration_Enhanced_Event 5000, 0x00, 0xfdfb, 0x00

Which we believe should turn off the periodic calibration, in testing this worked and we stopped seeing any regular jumps in the number of devices seen by a scan.

However we are not sure if this sequence is likely to have any side effects. This comes down to a discussion about what the period calibration is doing. The documentation describes all the tests as by default disabled, which suggests that stopping them should have no effects, but we are not sure about this and would like confirmation that disabling the periodic calibration during normal operation is harmless.

Thanks

Andrew Roca