Dear Sir/Madam,

Subject: Flashing/Connecting Issues with CC3220MODSF newly assembled boards (for few boards).

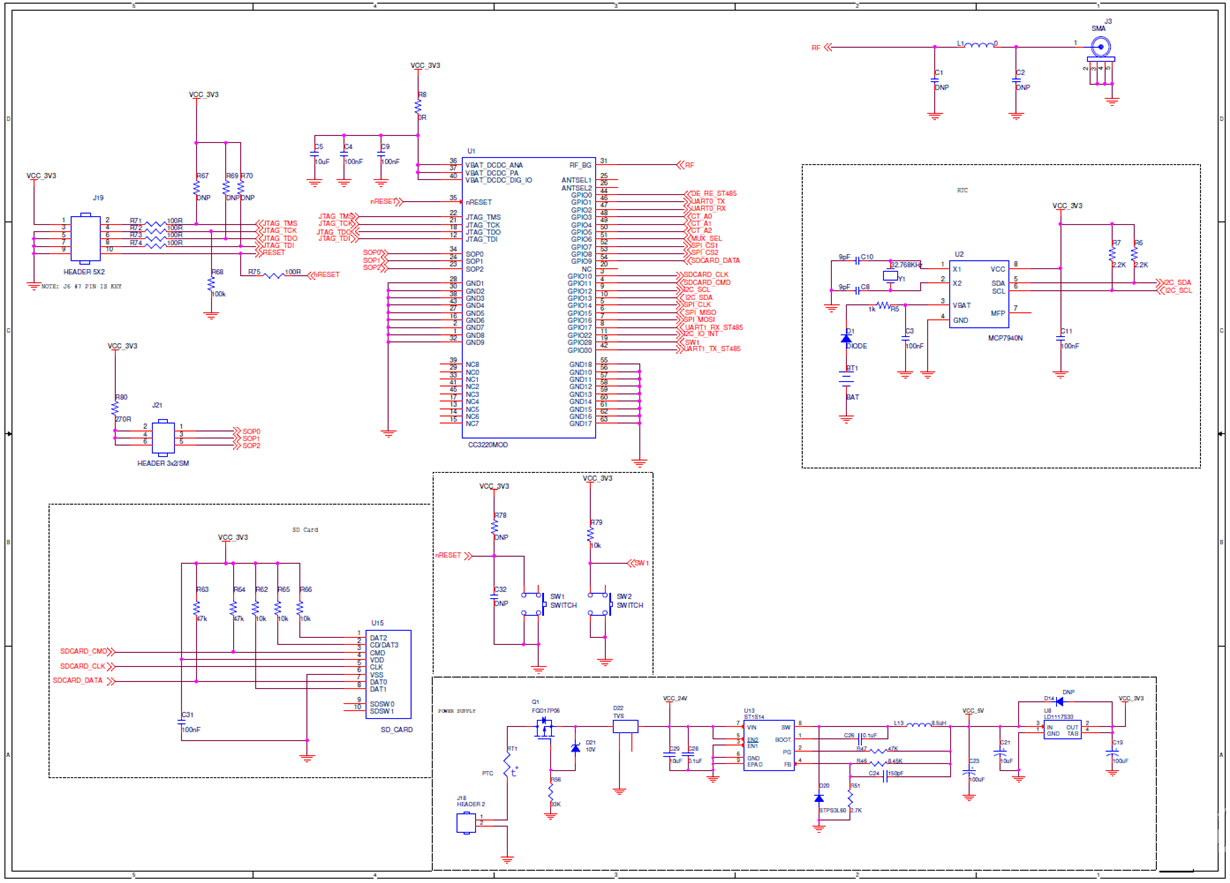

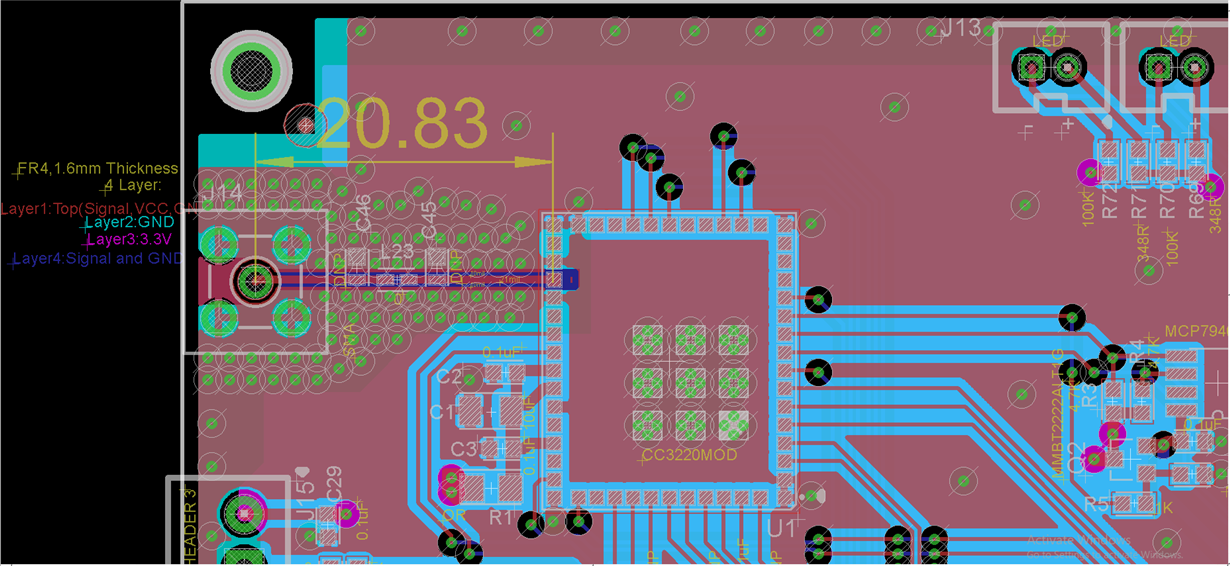

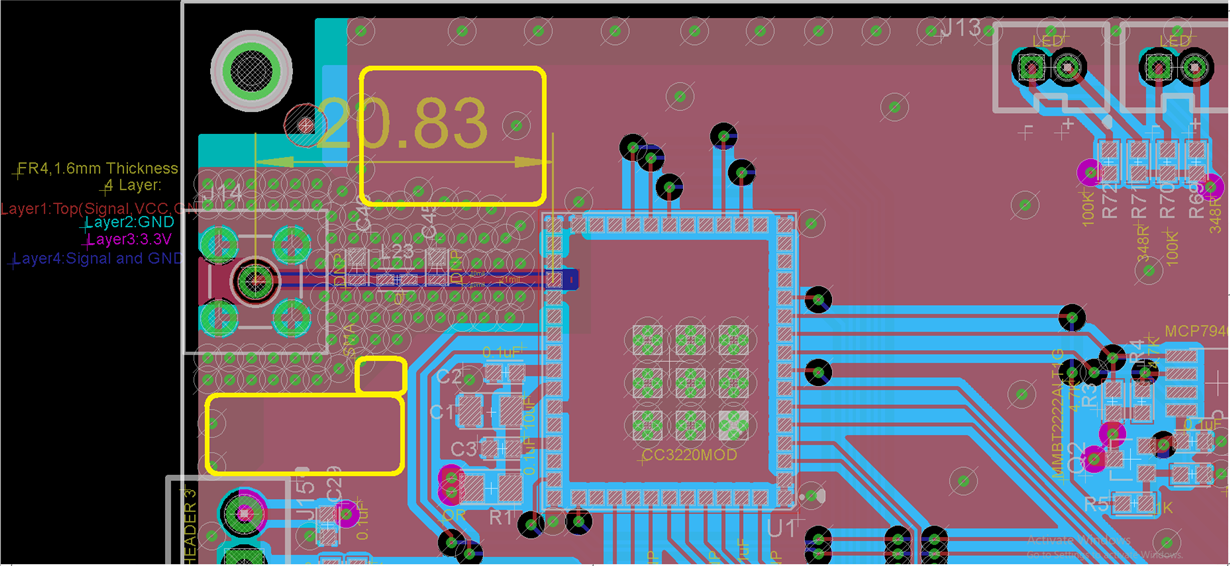

We are using CC3220MODSF & PFA the Schematic. We are using "CC3220MODASF LaunchPad" for programming(Flashing). We found "connection Fail" issues(Not able to Flash/programming) for Some board(more than 10 boards-Newly assembled) and remaining boards are working fine. We tried to trouble shoot the problem, but everything is looks fine and also we are getting 3.3V from onboard regulator output.

Kindly advise, what is the issues and provide the best solution.

Regards,

Naveen K