1st post here

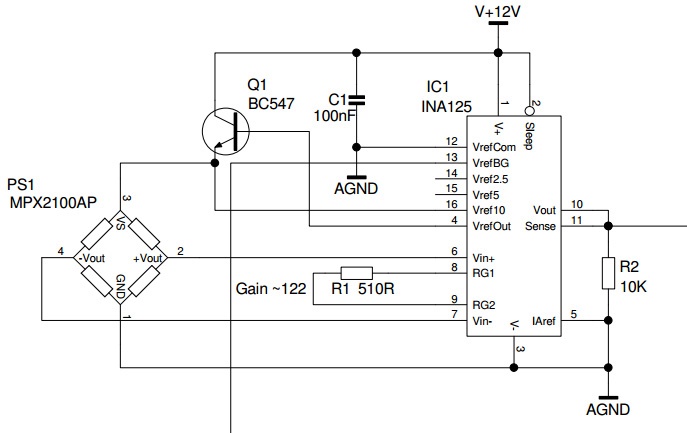

I'm building a pressure sensor circuit with the INA125 and a single supply. (See diagram) I did some searching here but could not see a solution.

I have it connected according to FIGURE 5. Single Supply Bridge Amplifier

The supply is really 13V to make sure I have enough after the voltage drop in the transistor. Nothing is connected to pin 13 (just in case) possible use as reference voltage for another circuit if it doesn't mess things up with this part of the circuit.

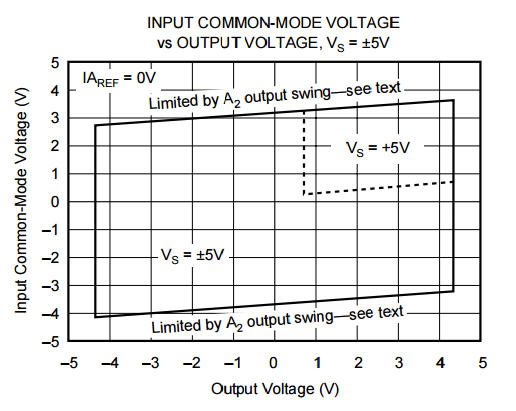

With the sensor connected I get the following:

Sensor supply 10.02V

Vout+ > V+in pin6 4.76V

Vout- > V-in pin7 4.33V

Output 11.95V

With the sensor disconnected I get the following:

Sensor supply 10.02V

Vout+ 5.03V

Vout- 5.0V

V+in pin6 0.27V

V-in pin7 1.52V

Output 11.89V

There seems to be a large voltage difference at the input of the chip messing up the sensor?? I tried another chip with the same results.

Any hints on getting it to work please? It's a new design and I like to use the chip as it keeps everything in one package. Additionally I have another project in the wings with a similar set if I get it to work.