Other Parts Discussed in Thread: C2000WARE, DRV8353

Tool/software:

Hello Team,

I am currently working on the implementation of the torque control mode using our own custom board.

We are able to run the motor in speed control mode using 48V encoder motor in all BUILD_LEVELS and we can able reach up to its maximum RPM in BUILD_LEVEL_4 (With encoder feedback).

First, I have tested TORQUE CONTROL MODE (Current control mode) in BUILD_LEVEL_3 because, in universal motor code TORQUE CONTROL MODE is implemented only for BUILD_LEVEL_3.

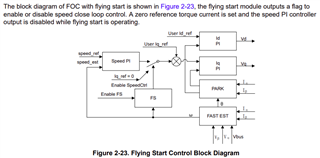

I'm trying to run the motor in torque mode in BL4, by surpassing the speed control loop because in BL4 only we can be able to apply the load and run the lab with complete FOC. I'm directly assigning Idq_set_A to IdqRef_A here same as BL3.

At lower RPM I am able to achieve the expected torque (29Nm) but in higher RPM like 2000 RPM or more than this I am not able to achieve the expected toque.

If I apply minimum load (4Nm) motor is stopping directly and, in this case, I am not getting any errors.

I want to know how much Id and Iq currents I need to inject in this case because in lower RPM it is working fine and in higher RPM only, we are facing this issue.

Apart from injection of Id and Iq currents, whether I need to check anything for this above issue?

Below I have mentioned the Id and Iq currents injected to achieve maximum torque at lower RPM (500RPM).

Id = 0 A, Iq = 230A

In this case we are not injecting Id current because has I know in lower RPM it is not required and it is required only to achieve maximum RPM, correct me if I am wrong.

Below I have shared the expected toque demand in different RPMs.

Thank you,

Regards,

Kirana H P