Hello All,

I recently purchased a TMP 006 evaluation module, tested it, and have been reading up on these forums & the datasheet. The end application is external body temperature measurement, so extremely low noise is critical. Some of my test results are shown below.

Figure 1: The response curve of the TMP 006 when going through cycle 23-25-27-30-33 degrees C

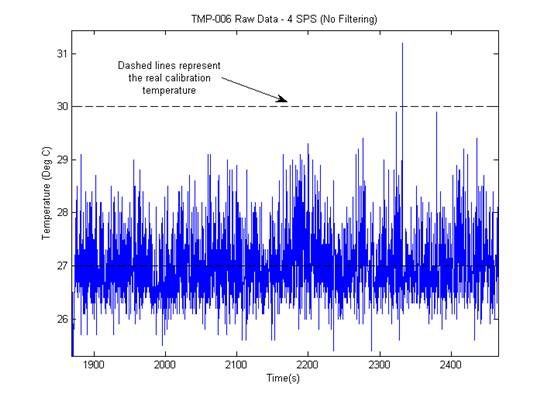

Figure 2: Zoomed in on noise at 30 degrees C step

These tests were performed under the following conditions:

- 4 SPS ("1 average")

- IR source is a calibrated black body rated for calibration of thermal cameras

- TMP 006 evaluation board powered and connected by USB to laptop

- TMP 006 evaluation board placed approx 1.5 inches from the black body in free room conditions (no coverings, exposed to external room environment)

I am interested in figuring out if there is some way that I can reduce this noise *without* filtering (analog or DSP). My questions are as follows:

1) On the evaluation kit, how is the filtering done? I assume that the TMP 006 simply takes multiple readings, and the software then does an average.

2) How well is the USB power supply filtered? I know that USB power tends to be very poorly regulated. I was thinking of using a ferrite bead and TPS7A49xx ultra low noise regulator to feed the TMP-006. Will a high-quality power supply with very low noise and high PSRR significantly improve noise response?

3) I understand from earlier posts that better readings can be obtained by shielding the sensor from external drafts (air currents) with say a plastic bag. Will this affect the sensor's performance in any way, or will it simply improve it by reducing noise?

I plan to construct a serious scientific solution soon. Any input on this would be appreciated.

Thanks,

Alex Behnaz