Other Parts Discussed in Thread: TAS2563, TAS2781, PPC3-EVM-MB, TPS61288

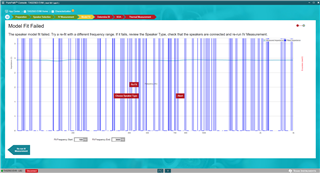

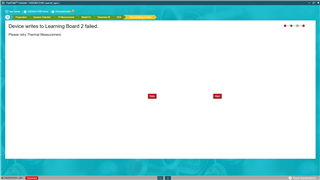

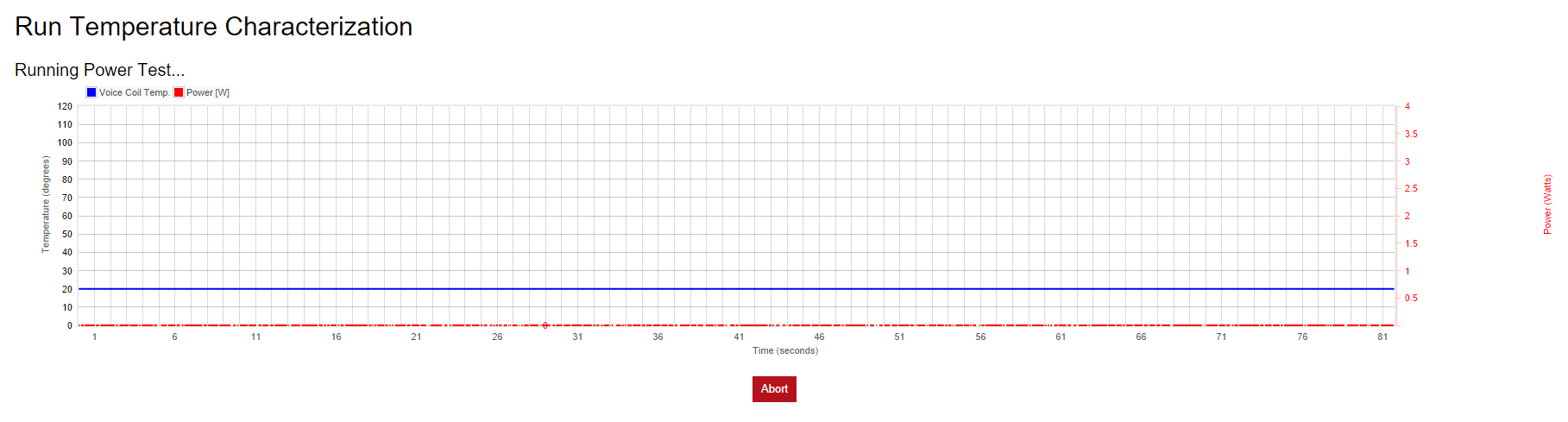

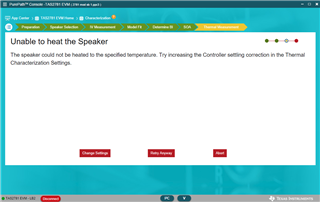

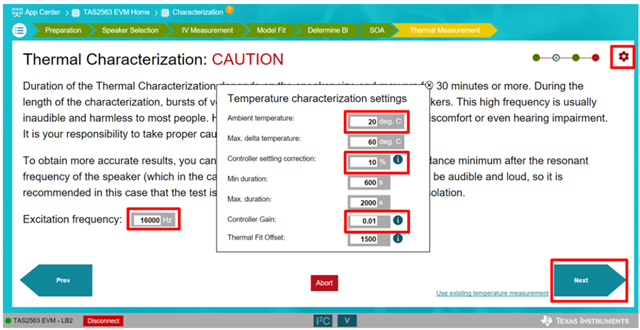

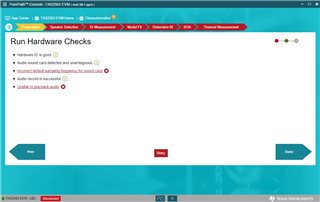

I'm using the TAS2563 EVM and module. It passes audio fine. When I connect the learning board in order to do speaker characterization, the audio checks don't pass, as in this screen:

I have verified that the audio settings are indeed 24bit 48KHz. Any suggestions on what to do