Tool/software:

Hi,

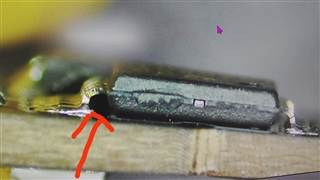

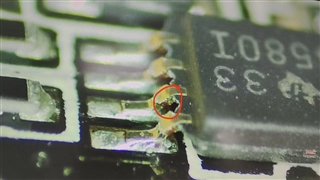

Our end customer relesae the order of RC4580TPWR to us and the good has some appearance issues, customer QE feedback 20pcs/ 20pcs all have this issue, please refer to below picture:

They want to know below:

1. Is this the quality problem or normal?

2. If this is the quality problem, we need to submit the FAR to TI CQE, right?

3. How long of the exposed copper pin to oxidize(CuO)?