Hi

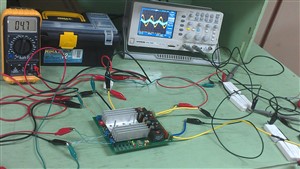

I make work a free sample of TAS5611a on my own PCB in BTL mode, I need to test the efficiency, then I use as a input signal a sinusoidal signal 1kHz of frequency, the same signal for each input, each output is conected to a load of 3.9 ohms.

I increase the input signal then the output power increase, the problem is that I can´t increase de output power above 16 W without the chip get very hot, the signals OTW1 and OTW2 get activate when the output power is above 16W.

How I can get a output power higher?

thanks