Hi,

can anybody help me?

We have a persisting problem on a borad we designed with the TAS5630B device.

First, a description of the application....

This is an audio amplifier module that fits a voice evacuation system in case of fire alarm.

The amplifier output is connected to a toroid 100V line transformer. The transformer is designed to handle 300W max, so the amplifier will provide this as a max power. Since the load connected to the transformer secondary is variable according to the number of loudspeakers installed, the amplifier will also see a variable load.

We followed all suggestions of a TI app note regarding transformer coupled amplifiers. Specifically, the transformer is designed for a 100Hz @ -3db bottom bandwidth, and the audio signal is cut at 150Hz with a 24dB/octave high-pass filter implemented on the DSP that feeds the amp. So, the transformer will never saturate.

As indicated by TI, the DSP mutes the amp until the amp is ready.

Power supply is linear, no switching, no PFC. Vdd is subject to mains fluctuations, but does never get above 52V @ 230Vac+10%

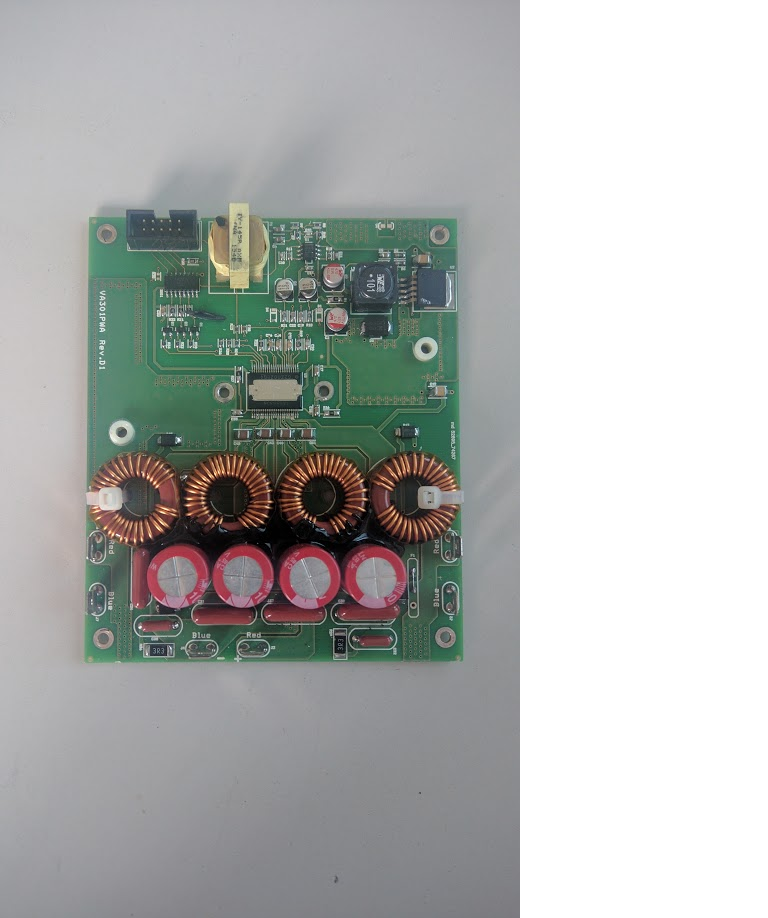

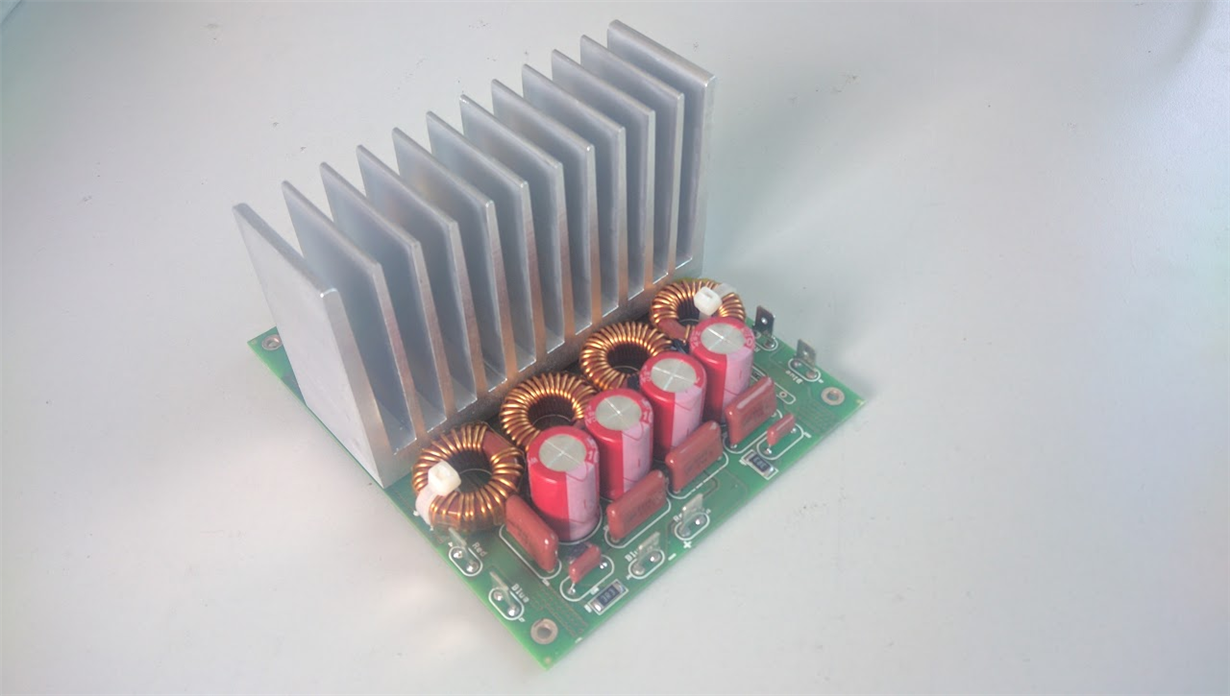

The device is PBTL configured and we designed a pcb the most similar as possible to the evaluation board. The indutors were custom made according to the specifications given by TI for the evboard.

The input stage a copy&paste of the evboard, except for the coupling transformer since in our application, the amp needs to be isolated from the mainboard. The same goes for the status reporting pins.

On the PCB we have ground plane on the bottom side. The top side we have the 50V Vdd rail that splis into 4 legs that feed each half bridge of the device. Cose to each half bridge we have ceramic decoupling caps.

Bootstrap capacitors are on the bottom side.

The heatsink is NON-anodized alluminium to give the required strong ground connection to the heat pad. Needless to say that the holed for the screws that hold the heatsink have pads connected to the ground plane.

I have attached here both schematic and PCB layout.

I have hand mounted 15pcs prototypes with the same PCB and same compoment values. None of them failed! With these boards we have smoothly passed both EN54-16 and UL846 lab tests and product certification.

TESTING. After manufacturing, each board is tested on an automatic fixture managed by a labview application that logs the test results.

The automatic test will measure the idle current, test the reset, test the gain and perform a 2minutes burn-in at full power (300W). The reason for the burn-in is to test the both electrical and thermal coupling of the device to the heatsink.

In order to implement similar field operating conditions, inside the test fixture the is a 100V coumpling transformer between the amp and the resistive load. The transformer is the the same that is fitted into the final application.

The same goes for the power supply: same power trasformer used for the final product.

All boards successfully pass this test. All give the same mesured data within a strict range (gain), but idle current may vary consistently from board to board: on 200 board tested, the lowest current that was measured was 140mA and the highest was 260mA @50V.

Once the amplifier board is installed in the application, the product is powered and tested from A-to-Z. The unit is loaded at its nominal and the unit is tested with a speech signal..

All units pass the functional test..

ISSUES, ISSUES, ISSUES...

Once the unit is sold and installed by the customer, the issues arise: the amp may randomly fail after short time from power-up, or after some several weeks.

We asked to have back the broken boards to investigate the problem. All seem to be in a permanent reset state. Idle current is few milliamps (buck, opamp, etc...), nSD and READY are set low. The only way to get the board working again is to remove the TAS5630B and put a new one on it.

For our company this is a catastrophic event because all units fail once in the customer's hands!

Our new product was freshly launched and on the first 200 boards batch, 40 of them got failed! The production manager has stopped manufacturing, sales gyus are beginning to have a consistent backlog and the boss is knocking at my door everyday!

ANALIZING TEST LOGS AND FAULT

Each board has a SN. This helped me to do some analysis. What I have found there is a sort of correlation between the faulty boards and the idle current. All boards that failed have idle current above 200mA.

HELP HELP HELP!

Can somebody help me to investigate this issue? I really have very few options left: fixing the problem (quickly) on this board release or designing a new one, bur for sure it will not be based on a TAS6530B anymore.....

A few points here I find hard to explain:

* why on a 20pcs batch the idle current spans over a so wide range (140-260mA)? What is this due to?

* does it make sense that the boards with high idle current are more prone to fail?

* why the hand mounted units never failed, but the production ones do?

* can the failure be caused by latch-up at power-on? The primary side of the line transformer that feeds the input state is capacitor coupled to a driver ic (i.e., an opamp)

I really need all and any suggestion to address further investigation.

Many thanks for your support

Marco