Hello,

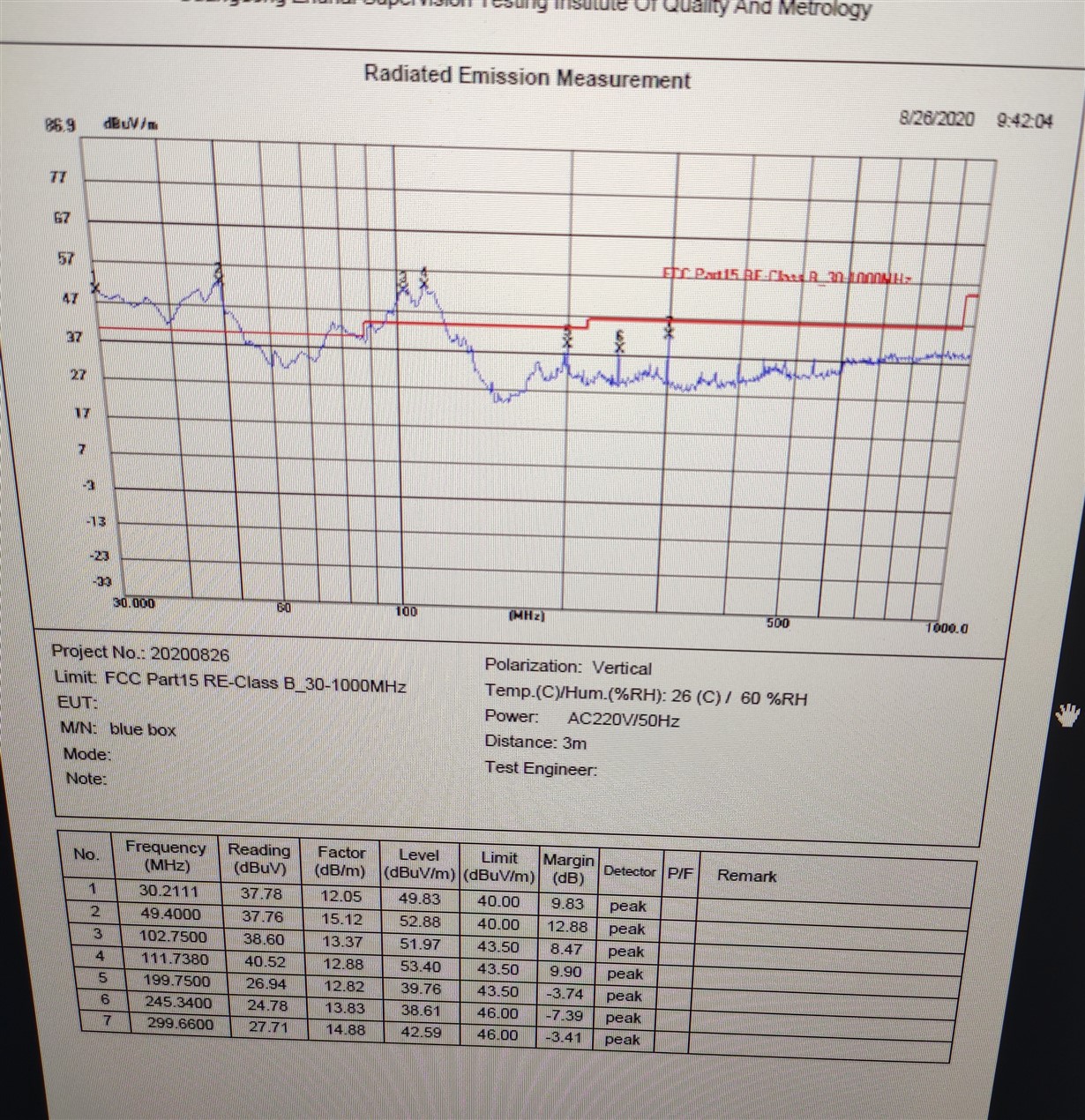

We are building a consumer product using two PCM3168A parts and are having trouble passing FCC testing.

Our design is in a small metal enclosure and uses two PCM3168A's. We have isolated the noise and believe it is coming from the audio section, including the codec. A previous design with a competitor's part passed FCC. So, we think the circuit surrounding the PCM3168A is the issue. It is below.

We added L16 on the second pass at the suggestion of our factory. It didn't seem to make much difference. MCLK, SCLK, FCLK, and MOSI have 100 Ohm series resistors in another drawing close to the MCU.

We're using both codecs in slave mode, single rate clocking, with an MCLK of 12.288 MHz.

Do you have any recommendations on how to reduce the noise? Are we missing anything?

Thank you very much.

Aaron Higgins