Hi,

I met a problem during I use ADS1230 to measure the output of a strain gauge. I found even the output of the strain gauge is close to zero, the AD result periodically be very high, the duration is from several seconds to several tens seconds.

I captured the waveform of DOUT/DRDY and SCLK and found if there is no any problem, the waveform is stable; however the data ready time is periodically changed.

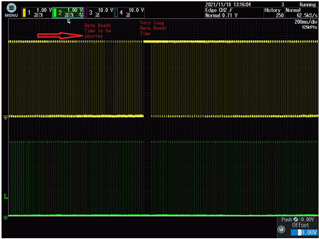

The waveform is as below:

CH1(Yellow) is the DRDY/DOUT, CH2(Green) is SCLK.

The data ready time is reduced from long to short and then becomes very long and then reduced cycle by cycle.

When this kind waveform appears, the AD result is not stable. A high value appears every seconds or several tens seconds.

In my design, I use the 21st SCLK to force DRDY/DOUT high. But I found sometimes the DRDY/DOUT can not be pull to high after 21st SCLK is available. Please see below picture for this case.

In the picture above, after 21st SCLK be available, the DRDY/DOUT be pulled to high after 11.92 ms. I am not sure why it needs so long time to drive DRDY/DOUT high.

In my design, the cycle of DOUT/DRDY is about 12.1ms.

And I would like to know if the DRDY/DOUT is not ready, for example in above picture if I send SCLK when DRDY is low without the high to low process, what will happen?

This phenomenon is firmware related, I have a firmware without any problem; but another version has problem. The algorithm and code is almost same, I don't know what causes this. The product with this software is OK in last half year but has problem in this month with 20% failure rate.

Would you please help to resolve this issue.

Thanks in advance!