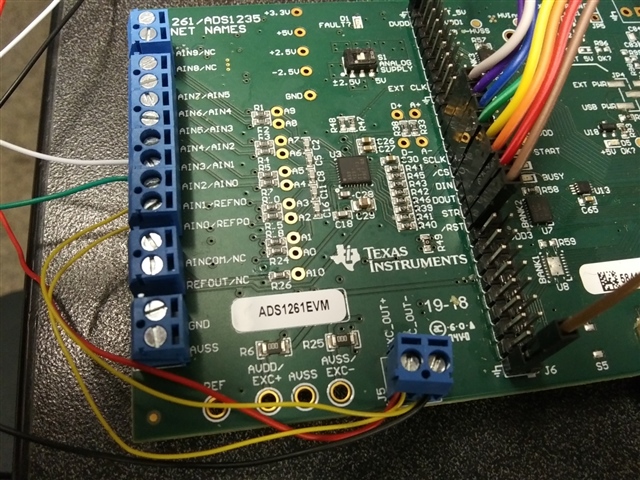

Other Parts Discussed in Thread: ADS1261, ADS1235

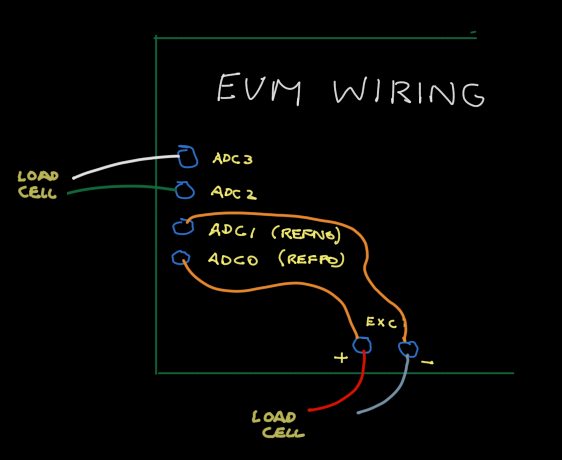

I am using the EVM with a separate ESP32 processor to drive the board.

I juper'd JP1 to tri-state the onboard processor as stated in the manual.

All works well .. Almost.

I send a 0x06 command and the 'echo' returns a 0x07 on MISO.

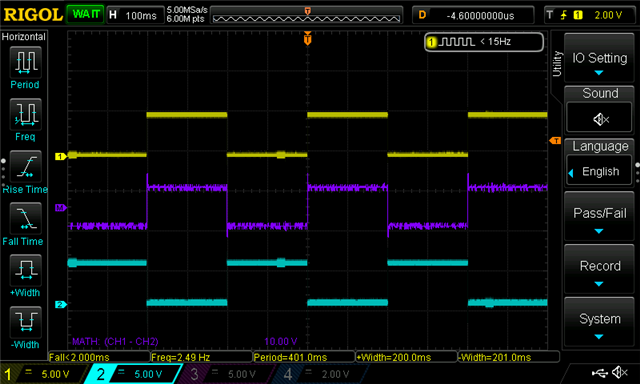

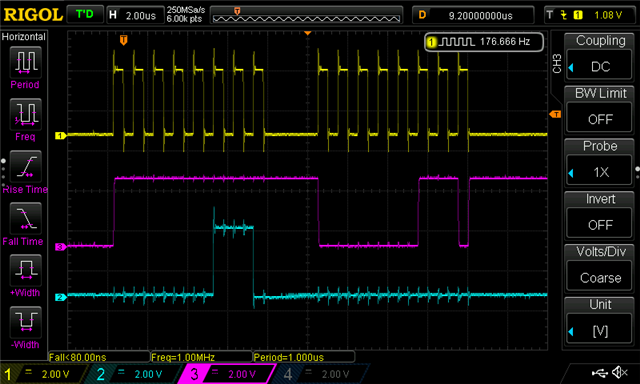

The scope traces tell the story ..

The first trace is the 'overview' .. sending a 0x06 and receiving (supposedly) a 0x06 back.

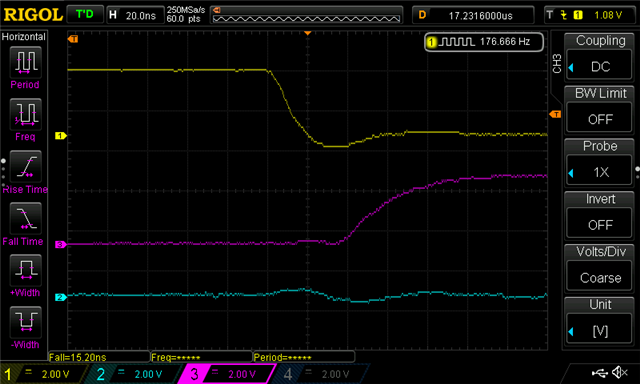

The second trace is a closeup of the last bit .. showing only 40ns for the ESP to catch the zero. It gets a one instead which is why I get a 0x07 back.

The ADS1261 only allows 40ns on the final bit instead of the 'normal' half clock.

This appears to be too fast for the ESP32.

Am I doing something wrong?

The clock is 1Mhz; MSB First; Mode1

The trace order on the scope images is,

Clock (yellow), MISO (purple), MOSI (blue).

Thanks, Tom