Hello TI experts,

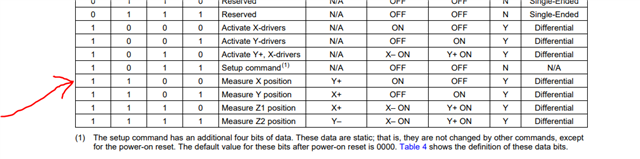

My customer tests TSC2007 with their product now, but there is a problem.

when they touch left of the screen, it works well. but if they touch right of the screen, it points more left than I touch.

I attach a video link for your convenience. (you can see it after 10 seconds of this video.)

I also attach a schematic. could you review it?

I think there are some calibration methods for this problem. please check this issue for me. Thanks.

Best regards,

Chase