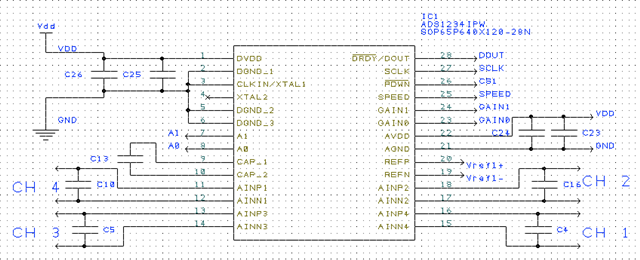

Out of a recent batch of devices, we've had 7 of the 12 ADS1234 chips in 4 of our units fail.

- 4 had the Dout pin constantly high

- 1 had the Dout pin constantly low

- The others seemed to have some kind of internal short between the clock pin and the Dout pin

We're using the devices in slow, 10SPS mode, and I think we've followed all of the data sheet advice.

Are there any known failure modes of the ADS1234?

I've got a theory that there could be voltages on the control pins before the supply voltage to the ADS1234 has stabilised, could that cause this kind of behaviour?

Any help so we can prevent a recurrence of this would be very gratefully received!

A