Other Parts Discussed in Thread: TLV8541

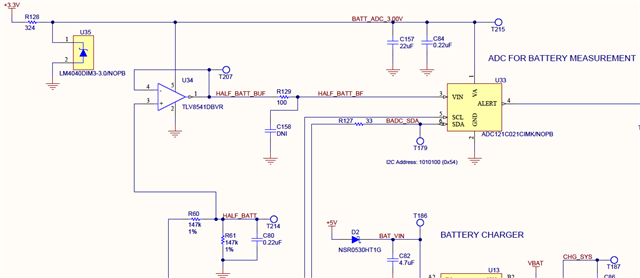

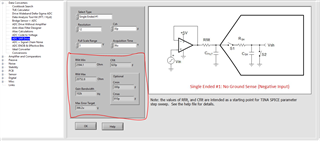

We're using the ADC to measure the voltage of an LFP battery. We divide the battery voltage by 2 and buffer it with an opamp, followed by an optional RC lowpass. The ADC is powered from a 3.0 V shunt reference; schematic is attached at the bottom of this posting. The input signal to the ADC is therefore 0 to 1.825 V.

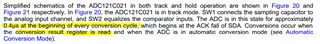

With the default circuit shown in the schematic, the accuracy of the measurement is fine over most of our range, but at both ends it is not: for VIN below about 0.2 V the ADC reads high by 10% and above 1.5 V it reads low by a few percent. We tried a few experiments. Changing the series resistor (R129) to zero ohms had no effect. Restoring R129 to 100 Ω and trying different capacitor values, we find that 100 pF at C158 fixes the problem. Larger capacitors caused the measured value to bounce around a bit -- maybe the opamp isn't happy with the capacitive load? A smaller capacitance such as 15 pF didn't give great results either.

We suspect that we're seeing interaction between the sampling capacitor and the outside world. This is not shocking, but what's surprising is how sensitive it is.

- What would cause the non-linearity we saw below 0.2 and above 1.5 V?

- Why didn't the direct connection of the opamp to VIN improve the performance?

- Is this part unusually sensitive?

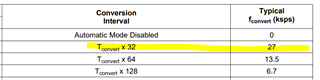

- Could any of the register settings impact this? Turning auto-conversion off vs. on seemed to have some effect, but why would that be?

Thanks,

Scott