Other Parts Discussed in Thread: ADS131M04, TIDA-010036, ADS131M02

How to calibrate the ads131m04evm offset and gain of the ADC?

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

How to calibrate the ads131m04evm offset and gain of the ADC?

Hello Kevin,

Please look at section 8.3.11 Calibration Registers in the ADS131M04 Datasheet.

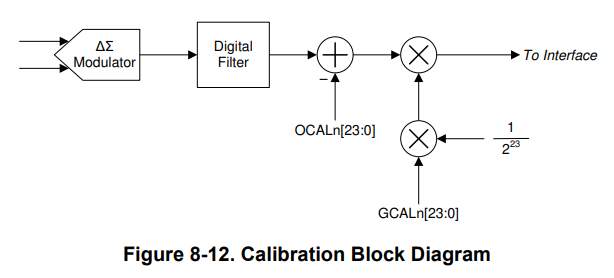

For a short summary, you'll be writing into 2 different registers: OCALn and GCALn. OCALn represents the offset and GCALn represents the gain correction.

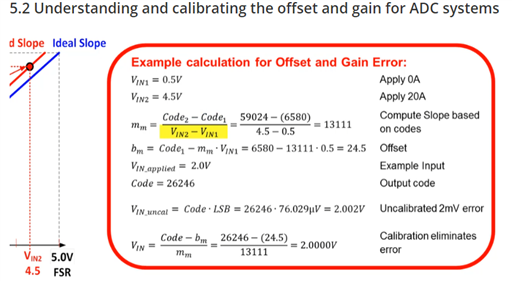

If you don't know how to obtain the gain and offset values, please watch this TI Precision Lab video lesson: https://training.ti.com/ti-precision-labs-adcs-ac-dc-specifications-offset-error-gain-error-cmrr-psrr-snr-and-thd?context=1139747-1140267-1128375-1139102-1128657 and the following lesson talking about other errors here: https://training.ti.com/ti-precision-labs-adcs-understanding-and-calibrating-offset-and-gain-adc-systems?context=1139747-1140267-1128375-1139104-1134080

Best,

-Cole

Hi Cole,

Thanks for answer. I know to calibrate the error through the two registers OCALn and GCALn, but I still want to write what value?

Do we have tutorials?

Another question

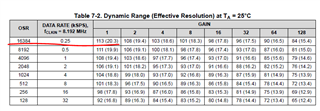

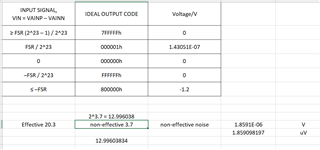

OSR@16384 GAIN@1, the effective resolution is 20.4, It will have 3.7 dead bits, and those dead bits will all turn into noise, right?

2^3.7 LSB becomes noise,converted to voltage is 1.89uV,right?

Hello Kevin,

but I still want to write what value?

Do we have tutorials?

As mentioned before, please check out the TIPL ADC videos I linked above. Here is a screenshot from the lesson:

As shown in the block diagram above from the datasheet section, the offset voltage is subtracted from the results so you simply need to write the code corresponding to the offset voltage into OCALn.

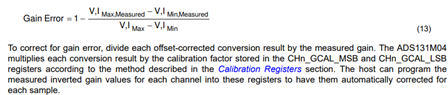

For GCALn, we have the procedure and equations in section 9.2.2.4 Calibration. There's also helpful info about OCALn. Here's a screenshot with the equation and general procedure for GCALn specifically.

There also might be something useful in the Example code, feel free to check it out:

.

OSR@16384 GAIN@1, the effective resolution is 20.4, It will have 3.7 dead bits, and those dead bits will all turn into noise, right?

2^3.7 LSB becomes noise,converted to voltage is 1.89uV,right?

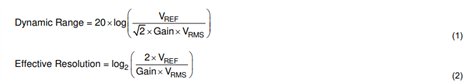

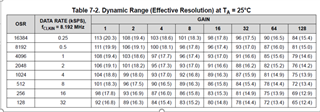

You are correct but there is one important concept I'd like to highlight. The concept of dynamic range and effective resolution are derived from noise, as shown in the datasheet and below:

So the noise table, Table 7-1, comes first and is measured on the ADC. Then we plug that into the equations above to get the specifications in the datasheet. So the table for that setting shows 1.9uV(RMS) and you calculated 1.89uV(RMS).

In other words, your math is perfect but it is a fundamental different perspective. The noise creates dead bits. Its pedantic but helps illustrate what is actually happening inside the ADC a bit more.

Feel free to check out the TIPL ADC video series on noise if you want to learn more: https://training.ti.com/ti-precision-labs-introduction-to-adc-noise?context=1139747-1140267-1128375-1140017-1140016 I think that series in combination with SAR and delta-sigma: Noise and drive considerations https://training.ti.com/ti-precision-labs-sar-delta-sigma-noise-drive?context=1139747-1140267-1128375-1147914-1148012 will you develop a solid foundational understanding of ADCs.

Best,

-Cole

Hi Cole,

Thanks for your patient explanation, I have learned to offset and gain calibration of ADS131M04EVM. But I have another question.

I calibrated the offset error and gain error for the ADS131M04EVM. But the voltage of about 15uV cannot be calibrated, how should it be calibrated?

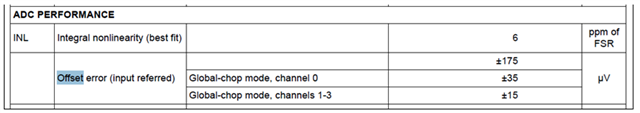

I noticed that the offset error of channel three is +/-15uV, is this the same parameter? Can this value be calibrated?

Thanks and looking forward to your reply.

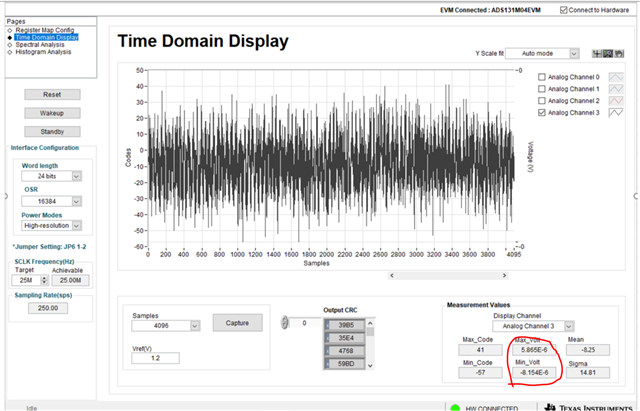

OSR@16384, GAIN@1, Channel 3

Hello Kevin,

Thanks for your patient explanation

No problem!

I noticed that the offset error of channel three is +/-15uV, is this the same parameter?

The +/- 15uV is a typical offset voltage that has nothing to do with noise. Offset is a DC error where noise relies on bandwidth (BW) and therefore, AC can be considered an AC error. When you were calibrating for offset, you should have noticed that the value probably fell within the +/-15uV if you translated codes to voltage.

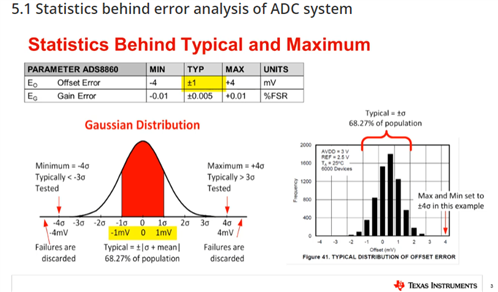

Anyways, the typical value is given as a range to help the user make statistical error decision based on the specification. You can learn more from the TIPL training video: 5.1 Statistics behind error analysis of ADC system. I've copied and pasted a very important slide about that discussion below.

But the voltage of about 15uV cannot be calibrated, how should it be calibrated?

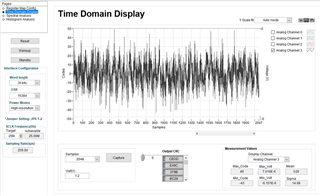

According to your screenshot, 15uV is in the units of Peak to Peak otherwise written as 15uV(pkpk). You might have noticed me write V(RMS) in the last response, most engineers like to discuss noise on context of the RMS value as statistics and the distribution (which you can get from the histogram tab of the GUI) show that getting the peak noise level is statistically unlikely where getting the RMS value is much more likely.

The quick rule of thumb for a gaussian distribution is that Vpkpk/8 = VRMS. So if I divide 15uV(pkpk)/8 = 1.875uV(RMS) which correlates to the noise specification that you were showing me earlier (f_data = 250SPS, G = 1). Alternatively, you should use the Mean value in your screenshot it, convert it to codes and you'll get a similar answer.

Other thoughts:

So far, every question of yours has been related to a TIPL video. I would highly recommend you watch those first and check the main FAQ for more learning:

Best,

-Cole

Hi Cole,

Thanks for support.

When you were calibrating for offset, you should have noticed that the value probably fell within the +/-15uV if you translated codes to voltage.

Yes, this effect can be achieved after calibration in fact.

I'm in favor of using noise as a RMS value that is more normal and the mean value displayed by the host computer is also very small after calibration.

I have a question whether this Mean value is an average value or a RMS value? Then how can the customer's MCU get this value? Is there a corresponding register or what?

Hi Kevin,

Yes, this effect can be achieved after calibration in fact.

Actually, this should have been the case before calibration.

I have a question whether this Mean value is an average value or a RMS value? Then how can the customer's MCU get this value? Is there a corresponding register or what?

Good point, I misspoke earlier. The equation between RMS and mean and sigma (standard deviation) is as follows:

RMS^2 = Mean^2 + Sigma^2

So, if there was no DC error offset (or Mean = 0), then the standard deviation would equal the standard deviation. So, Sigma in the GUI is the noise in RMS, I'll edit my previous response. There's assumptions here that you successfully calibrated out DC error but it seems correct when I do the math.

All of the this is calculated in the GUI, so there's no registers for the customer to go and grab this information. Our GUI's use labview derived libraries and equations, if I'm not mistaken. The GUI grabs the raw ADC codes and then looks at all the samples and calculates this information. The MCU or processor of the customer would have to calculate this stuff on their own if they want it in their system but that isn't always needed at run time in a real system.

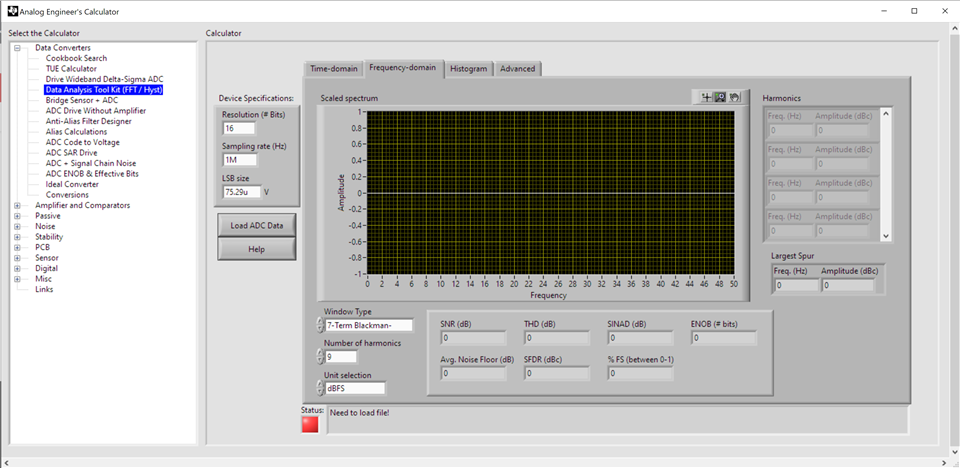

At this point, I'm confused what the needs are from the customer. If the customer wants to see the ADS131M0x performance in context of offset, then the GUI is good enough. If they want more calculations they can throw their data in the Analog engineer's calculator and take a look at noise floor, THD, SNR, etc. Or if they are good with MATLAB or labview, they can do it themselves with raw data collected from the GUI.

Best,

-Cole

Hi Cole,

So, if there was no DC error offset (or Mean = 0), then the standard deviation would equal the standard deviation. So, Sigma in the GUI is the noise in RMS, I'll edit my previous response. There's assumptions here that you successfully calibrated out DC error but it seems correct when I do the math.

The mean can be calibrated very close to 0, but the standard deviation is still very large.

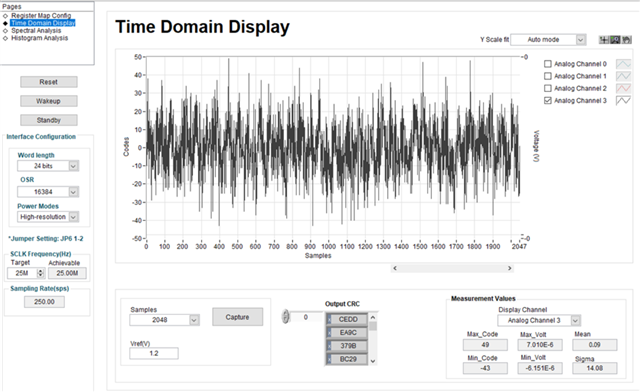

In this case, mean is 0.09 and sigma is 14.08.

Customer want to test accurately 10uV input signal, ADS131M04 can do it?

What parameters should we recommend customers to use?

At this point, I'm confused what the needs are from the customer. If the customer wants to see the ADS131M0x performance in context of offset, then the GUI is good enough. If they want more calculations they can throw their data in the Analog engineer's calculator and take a look at noise floor, THD, SNR, etc. Or if they are good with MATLAB or labview, they can do it themselves with raw data collected from the GUI.

Last time I confirmed with the customer that their MCU will process the data, but he is not clear how to deal with the customer.

I need to confirm again.Hello Kevin,

the standard deviation is still very large.

As a reminder, sigma is in codes. So:

Looks like you're around the noise spec to me.

Customer want to test accurately 10uV input signal, ADS131M04 can do it?

As an FYI, here's a TI reference design with the ADS131M0x family: https://www.ti.com/tool/TIDA-010036

![]()

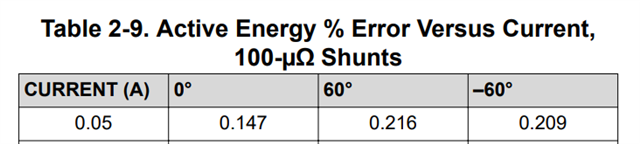

They use a shunt resistor on the input of the ADS131M04 and they're able to measure 50mA with 0.0625% accuracy.

Quick math shows they're measuring: 0.05*100*10^-6 = 5uV with 0.147% accuracy. So, yes, its possible and the TIDA-010036 had data to prove it. Note, e-metering has a pretty well known signal at 50/60Hz and their calibration process includes phase correction so it is in depth. I'm not sure how easy it will be for the customer's project.

Let me know if I missed anything.

Best,

-Cole

Best,

-Cole

Hi Cole,

Sorry for long time not reply. Customer have already designed our ADS131M02 device, so thank you technical support.

And customer have another question, Customer want to know the ADC ENOB how to calculate? Customer base on this: ENOB = (SNR-1.76) / 6.02.YT

This is right?

ENOB = (SNR-1.76) / 6.02

Best,

-Kevin

Hi Kevin,

Good to hear.

Customer want to know the ADC ENOB how to calculate?

Looks like I already answered it. Effective Resolution = ENOB

The concept of dynamic range and effective resolution are derived from noise, as shown in the datasheet and below:

So the noise table, Table 7-1, comes first and is measured on the ADC. Then we plug that into the equations above to get the specifications in the datasheet. So the table for that setting shows 1.9uV(RMS) and you calculated 1.89uV(RMS).

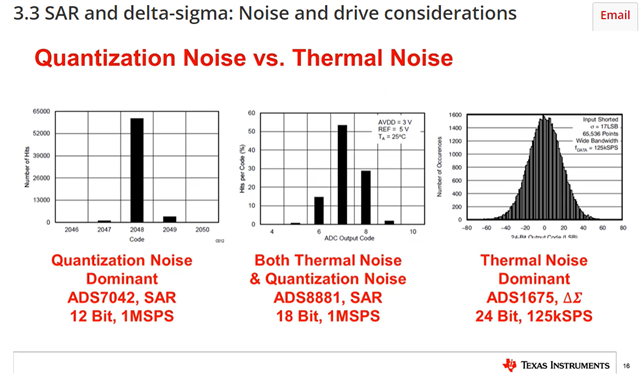

The equation provided:

ENOB = (SNR-1.76) / 6.02

is applicable when the quantization noise is the dominant source of noise of the ADC. Higher resolution converters are usually dominated by thermal noise. This is outlined in the SAR and delta-sigma: Noise and Drive Considerations TIPL video: https://training.ti.com/ti-precision-labs-sar-delta-sigma-noise-drive?context=1139747-1140267-1128375-1147914-1148012

Best,

-Cole

Hi Cole,

Hope you are all well. I have a question about the ADS131M02 PGA.

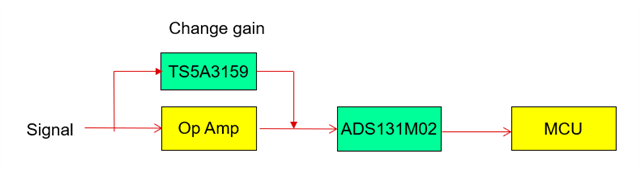

MCU sample input signal application

1. When the input signal normal, the signal delivery of the ADC may be amplified at 30 gain;

2. When the input signal is very small, we need to change switch and get the signal amplified at 60 gain;

So my question is that when input signal is very small, I keep the gain of the op amp at 30 gain, then I adjust the gain of the ADC to 2, can this achieve the same effect?

Best,

Kevin

Hi Kevin,

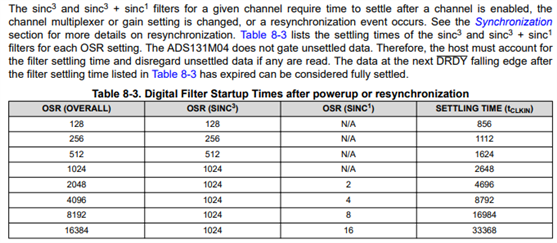

This is allowed and makes sense to cascade gain stages. Just be aware that the filters need to resettle when the gain is changed.

Best,

-Cole