Hello,

I am using an ADS1115 A/D in a test application (details described below). Twice now, this part has failed, but (so far) I have not found that I misusing the part in any way. Unfortunately, I don't have exact information about how long it took the part to fail, but it's safe to assume it was running continuously for at least 40 hours.

Application conditions:

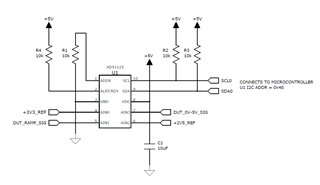

- VDD = 5VDC

- Connected to microcontroller via I2C bus.

- Analog inputs are connected as follows:

- AIN0: Connected to 3.3VDC reference voltage

- AIN1: Connected to a 0.0V to 3.3V, ramp-shaped signal, with a very slow period (about 1 minute).

- AIN2: Connected to 2.5VDC reference voltage.

- AIN3: Connected to an analog signal, output from a device-under-test. 0V to 5V.

- All measurements are single-ended, no differential measurements.

- Measurements for signals connected to AIN0, AIN2, and AIN4 are single-shot measurements, PGA gain set to 2/3.

- Measurement for signal connected to AIN1 is a continuous-mode measurement, PGA gain set to 1, sample rate set to 860 samples per second (maximum sample rate for this part).

Failure mode:

- Device still communicates over I2C and reports A/D readings, but A/D readings are off by about 100-200 counts. All four channels are reporting this same drift.

- Device is much hotter than normal, as in, too hot to touch. Spraying the IC with freeze spray causes the A/D readings to temporarily return to its former accuracy, but it quickly heats up and drifts again.

I'd like to know if you have any suggestions, or if you have seen anything like this before. Would you expect any problems with continuously running the part at its maximum sample rate? I didn't see anything in the ADS111x datasheet that said this would be a problem. Any information or insight you can provide would be helpful.

Thanks very much!

Regards,

-Michael