Other Parts Discussed in Thread: ADS124S08,

We have ADS124S08 EVM. We set analog input range from 0V to 5V. But at that time accuracy is not good as compared to vref=+/-2.5V.

Could you please help me on this, why this has been happened?

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

We have ADS124S08 EVM. We set analog input range from 0V to 5V. But at that time accuracy is not good as compared to vref=+/-2.5V.

Could you please help me on this, why this has been happened?

Hi Neel Shah,

Can you give more detail as to what you are seeing and how you have setup and configured the EVM? What were you expecting and what are you seeing as conversion data?

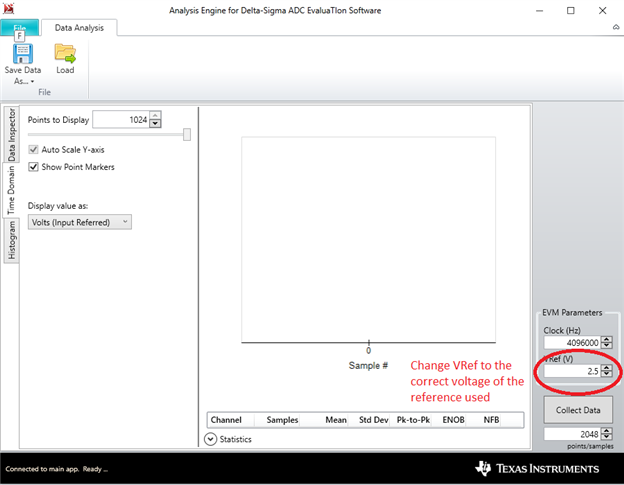

Something to consider is when using a 5V reference, you will need to adjust the value of voltage on the Time Domain plot in Data Analysis in the GUI. The default value is 2.5V, and you would need to change the value to 5V.

Best regards,

Bob B

We did some below modification in EVM at ADC SPI communication.

We have unmounted the U5 and U7 IC's and those will be connected to STM32U575 EVM and then measured the value which is showing below.

| Current measurement | |||||||

| Applied Current(mA) From NI Card | Measured Voltage(DMM 4050 Reading) | Calculated Current based on the DMM measured Vol. I(mA) = (V/R)*1000. | Measured Current(mA) AIN11 |

%Error | Shunt Resistor(Measured using DMM 4050) | 100.2 | |

| 1 | 0.09999 | 0.9979 | 0.9936 | -0.4313 | |||

| 2 | 0.2 | 1.9960 | 1.9886 | -0.3711 | |||

| 3 | 0.3 | 2.9940 | 2.9835 | -0.3511 | |||

| 4 | 0.4 | 3.9920 | 3.9787 | -0.3336 | |||

| 5 | 0.5 | 4.9900 | 4.9732 | -0.3371 | |||

| 6 | 0.6 | 5.9880 | 5.9675 | -0.3427 | |||

| 7 | 0.7 | 6.9860 | 6.9623 | -0.3396 | |||

| 8 | 0.8001 | 7.9850 | 7.9575 | -0.3448 | |||

| 9 | 0.9001 | 8.9830 | 8.9522 | -0.3432 | |||

| 10 | 1.0001 | 9.9810 | 9.9469 | -0.3420 | |||

| 11 | 1.1 | 10.9780 | 10.9402 | -0.3447 | |||

| 12 | 1.2 | 11.9760 | 11.935 | -0.3427 | |||

| 13 | 1.3 | 12.9741 | 12.9291 | -0.3465 | |||

| 14 | 1.4001 | 13.9731 | 13.9248 | -0.3453 | |||

| 15 | 1.5001 | 14.9711 | 14.9197 | -0.3430 | |||

| 16 | 1.6001 | 15.9691 | 15.914 | -0.3448 | |||

| 17 | 1.7001 | 16.9671 | 16.9088 | -0.3434 | |||

| 18 | 1.8001 | 17.9651 | 17.9039 | -0.3405 | |||

| 19 | 1.9002 | 18.9641 | 18.8984 | -0.3463 | |||

| 20 | 2 | 19.9601 | 19.894 | -0.3311 | |||

Software register configuration is shown below.

Value : 0xBC

AIN11 Channel selected.

MUXP - AIN11, MUXN - AINCOM

| SYS_ADDR_MASK | Value : 0x10 | SPI Timeout Disable,CRC Disable | |

| IDACMAG_ADDR_MASK | Value : 0x07 | IDAC Mag: 1mA | |

| IDACMUX_ADDR_MASK | Value : 0xF5 | Current source Channel No : AIN5 | |

Error is higher than expected. could you please advise me on this why error is higher?

Thanks in advance.

Hi Neel Shah,

There may be some misconception on the use of the EVM. First of all you didn't need to remove U5 and U7. The EVM was designed to disable the level shifter interface if the onboard micro is held in a reset state by installing jumper JP1. Second, components used on the EVM are used for demonstration purposes and not a complete system. The EVM was designed to demonstrate how sensors can be connected. The components themselves may not provide the best performance and temperature coefficients for a system. R78 is one example where the resistor is 0.1% and 25ppm tempco.

Next, you have not provided jumper settings or all of the register configurations being used. It is curious as to why you are giving me information regarding the IDACs, but not information regarding the PGA settings or the reference settings which will directly impact your measurement. So please send me all registers settings used.

As your error appears to be roughly the same throughout the measurement, calibration is probably in order. One thing that is not clear is how the shunt resistor was evaluated for resistance. As this is a 0.1% resistor, the maximum resistance should be 100.1 and you are measuring 100.2. So right here you have an inaccuracy. If you use a 2 point calibration, you should see an improvement. Also it is unclear if you issued the SFOCAL command to remove ADC offset.

As I don't know which reference you are using, there may also be some error related to the reference value used in computation. All of these error sources contribute and why calibration is important.

Best regards,

Bob B

Hi BoB,

Thanks for sharing your concerns.

-> Yes,you are right. Due to some internal team discussion reasons. We removed that shift registers.

->Jumper setting and register configuration details has been sown below.

PGA for Voltage and current measurement is 1 and for RTD measurement PGA set 4.

In EVM for measuring 0 to 5V external REFP0 and REFN0 used for voltage/current measurement. for Enable REFP0/REFN0, from the Software We have set Reference Control Register(05) value is 0x00. From the EVM Hardware, JP8 Connected to AVDD and JP11 Connected to Ground.

We have used REFP1 and REFN1 for RTD measurement and configured Reference Control Register(05) value is 0x06.

-->SFOCAL Command not used.

Thank you.

Best Regards,

Neel Shah

Hi Neel Shah,

When using the AVDD as the reference, both the positive and negative reference buffers should be disabled. When using the high-side reference on the EVM for RTD type measurements, both reference buffers should be enabled. Using the SFOCAL helps to remove offset of the ADC internals.

As I said previously, calibration should make a significant difference in the overall accuracy.

Best regards,

Bob B

Hi Neel Shah,

That is not correct. R89 and R62 have nothing to do with the reference and would only be used for a thermocouple measurement. The pullup and pulldown resistor is used to ensure that the thermocouple is within the correct input range of the ADC/PGA at mid-analog supply ((AVDD-AVSS)/2). A secondary purpose is for automatically determining that a broken wire has been detected as the conversion result will be full-scale (AIN2 is pulled to AVDD and AIN4 is pulled to AGND). For the thermocouple measurement the internal 2.5V reference is used and when pulling the inputs to the supply rail (either with AVDD=3.3V or 5V) the input will exceed the reference voltage and the conversion result is positive full-scale.

The resistors are not populated due to the ability to set the correct input range using VBIAS and open wire detection using the burnout current sources when measuring thermocouples.

Also, for a thermocouple measurement you would not use the REF1 reference or the IDAC currents. Normally you would not use AVDD as the reference input for thermocouples unless you would voltage excite the measurement so that it becomes ratiometric. Otherwise the AVDD supply would be much noisier than the internal 2.5V reference and would also have greater drift.

I would recommend reviewing the ADS124S08EVM scripts that setup the various measurements to determine which inputs and references are used when connecting the sensors to the EVM. There is also detailed information in the EVM user's guide.

To use the AVDD as the reference you would need to appropriately select the AVDD jumper setting at JP8, the AGND setting on JP11, and configure the ADC to use reference REF0 reference.

Best regards,

Bob B