Hello TI Team,

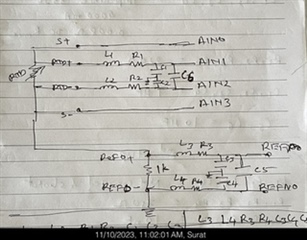

We make circuit using ADS114S08 to measure temperature.

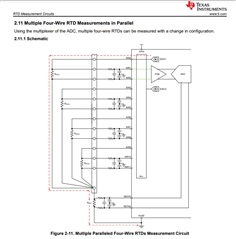

In our system we connect 4 number of 4 wire RTD in parallel as per application note : " A basic guide to RTD measurements ".

When we measure temperature, noise is present.

So how to calculate RC low pass filter value and corner frequency for these multiple RTD ?

So that we can remove noise from each other and no affect on other channel when we measure one channel.