Other Parts Discussed in Thread: MSPM0G3507, , LP-MSPM0G3507, SYSCONFIG,

Hello TI,

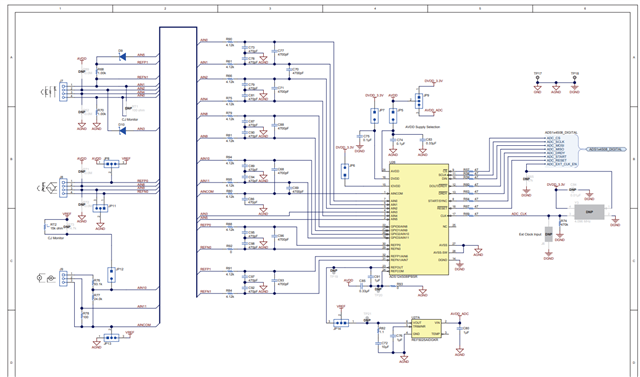

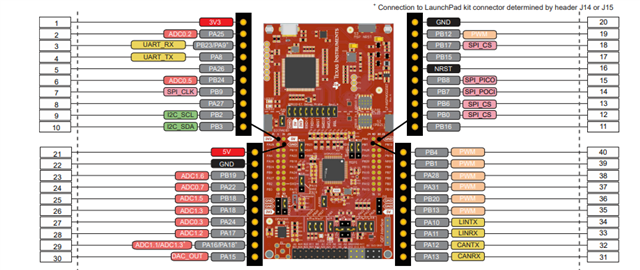

I am interfacing 3 wire RTD PT1000 sensor with ADS124S08 and MSPM0G3507.

Reference circuit/Schematic is ADS124S08 datasheet example page no. 91.

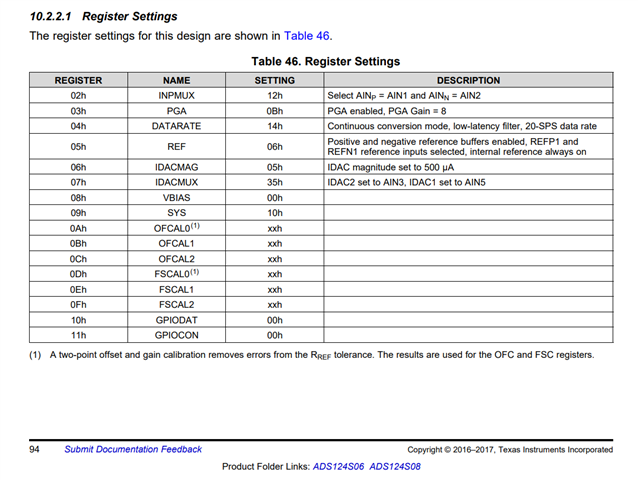

Below are the register setting.

int main (void)

{

delay_cycles(80000); //2.2ms delay as per data sheet of ads124s08

SYSCFG_DL_init();

DL_GPIO_clearPins(GPIO_SPI_0_CS0_PORT,GPIO_SPI_0_CS0_PIN); //cs low

delay_cycles(16000);

DL_SPI_transmitData8(SPI_0_INST,RESET_OPCODE_MASK); //reset device

delay_cycles(128000);

regWrite(REF_ADDR_MASK,0x06);

regWrite(PGA_ADDR_MASK,0x0A); //0A// PGA enabled, Gain = 4

regWrite(INPMUX_ADDR_MASK,0x12); //12// Select AINP = AIN1 and AINN = AIN2

regWrite(IDACMAG_ADDR_MASK,0x07); //07// IDAC magnitude set to 1mA

regWrite(DATARATE_ADDR_MASK,0x14);

regWrite(SYS_ADDR_MASK,0x10);

regWrite(IDACMUX_ADDR_MASK,0x35); //35;// IDAC1 set to AIN5, IDAC2 set to AIN3

readRegs(INPMUX_ADDR_MASK,5,Data); //trying to read 5 register starting from register address 0x02

DL_SPI_transmitData8(SPI_0_INST,START_OPCODE_MASK); //start command

delay_cycles(16000);

DL_GPIO_setPins(GPIO_SPI_0_CS0_PORT,GPIO_SPI_0_CS0_PIN); //cs high

while (1)

{

if (!DL_GPIO_readPins(GPIO_LEDS_DRDY_ADC_PORT, GPIO_LEDS_DRDY_ADC_PIN)) //waiting for DRDY pin to goes low

{

DL_GPIO_clearPins(GPIO_SPI_0_CS0_PORT,GPIO_SPI_0_CS0_PIN); //cs low

delay_cycles(16000);

DL_GPIO_setPins(GPIO_LEDS_START_PORT,GPIO_LEDS_START_PIN); //testing

delay_cycles(16000);

DL_SPI_transmitData8(SPI_0_INST,RDATA_OPCODE_MASK);

#if 1

for(int i=0;i<3;i++)

{

Input_Data[i] = DL_SPI_receiveData8(SPI_0_INST);

}

#endif

delay_cycles(16000);

DL_GPIO_setPins(GPIO_SPI_0_CS0_PORT,GPIO_SPI_0_CS0_PIN);

}

}

}}

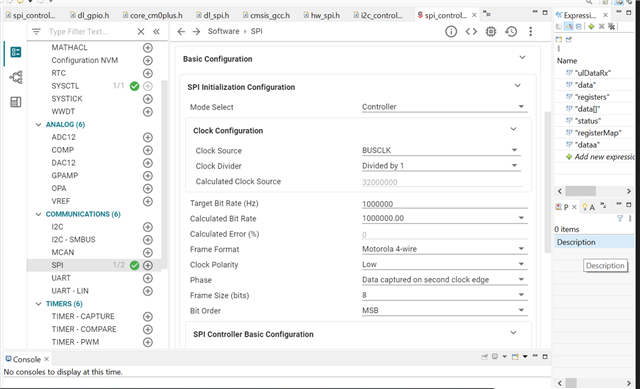

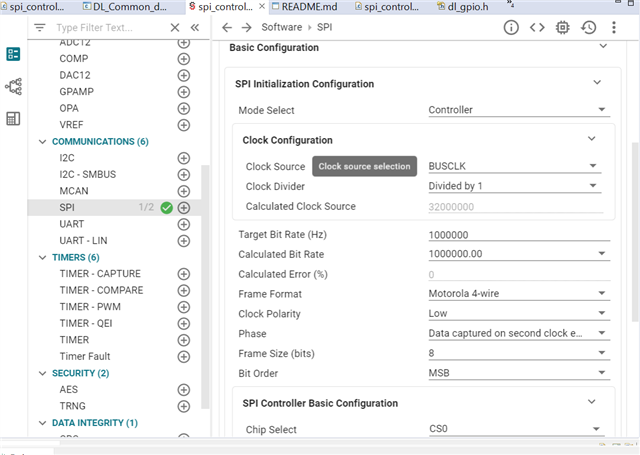

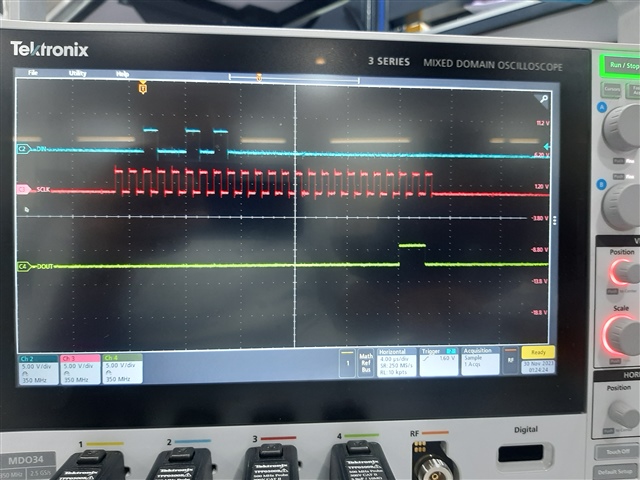

SPI setting

- SPI Mode 1

- clock bit rate 1MHz

- Bit order - MSB first

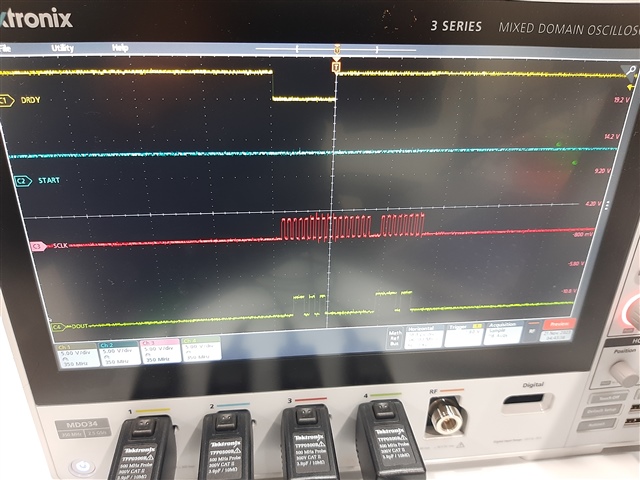

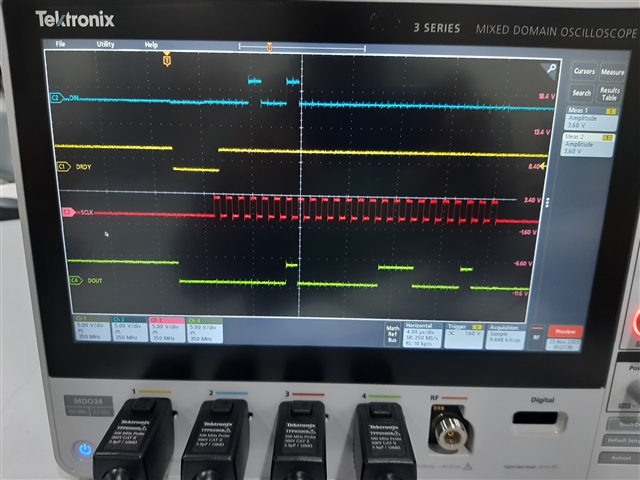

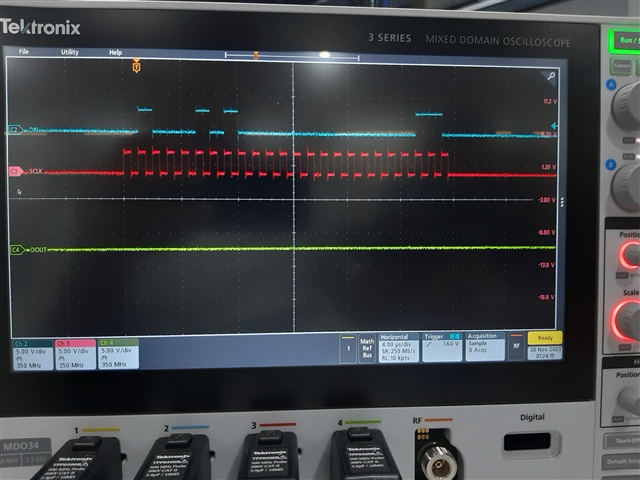

We followed datasheet pseudo code but not getting data from ADC. When reading SPI RX buffer some random value comes.

We are not sure ADC get configured or not.

IDAC magnitude not set as per setting 500uA.

.

.