Tool/software:

Hello

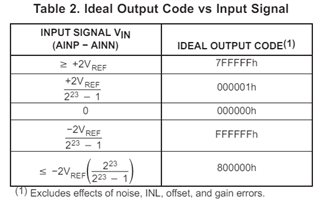

I am woking on a project with the old sensor ADS1222. After establishing the SPI connection to MCU, 3 bytes of 0xFF could be read. After a while, the sensor got stable with the values down to 0x00. And then the sensor always returned values of 0x00 even though pressure was applied.

Below are some configuration:

1500kHz clock source connected to CLK pin.

Transfer rate is setup at 1Mhz.

Transfer mode is continuous.

MUX 0 is selected

Please let me know if more detail is required.

Thanks in advance for your support!!